Programming manual

CNC 8055

CNC 8055i

IRREGULAR POC

K

ET CANNED CYCLE

11.

·M· & ·EN· M

ODELS

S

OFT

: V02.2

X

·255·

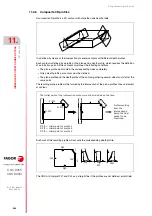

3D pockets

11.2.3

Finishing operation

This operation is optional.

It will be programmed in a block that will need to bear a label number in order to indicate to the canned

cycle the block where the finishing operation is defined.

The function for the finishing operation is G68 and it cannot be executed independently from the G66.

Their programming formats are:

G68 B L Q J I R V F S T D M

[ B5.5 ] Drilling peck (step)

Defines the pass in the plane between two 3D paths of the finishing operation. It must be defined

and with a value other than "0".

[ L±5.5 ] Lateral finishing stock

Defines the value of the finishing stock on the side walls of the pocket left by the roughing and semi-

finishing operations. There is no finishing stock left on top of the islands nor on the bottom of the

pocket.

If programmed with a positive value, the finishing pass will be carried out in square corner (G07).

If a negative value is programmed, the finishing pass will be carried out in G5 (round corner). If not

programmed, the cycle assumes "L0".

[ Q 0/1/2 ] Direction of the finishing pass

Indicates the direction of the finishing pass.

Q= 1:

All the passes will be inward from the top of the pocket to its bottom

Q= 2:

All the passes will be outward from the bottom of the pocket to the top.

Q=0:

Alternating direction for every 2 consecutive paths.

Any other value will generate the corresponding error message. If parameter "Q" is not programmed,

the cycle assumes Q0.

; Definition of irregular pocket canned cycle.

G66 R100 C200 F300 S400 E500

; Defines the finishing operation.

N300 G68...

Summary of Contents for 8055 EN

Page 1: ...CNC 8055 M EN Programming manual Ref 1711 Soft V02 2x...

Page 8: ...8 Programming manual CNC 8055 CNC 8055i SOFT V02 2X...

Page 12: ...12 CNC 8055 CNC 8055i Declaration of conformity and Warranty conditions...

Page 16: ...16 CNC 8055 CNC 8055i Version history...

Page 22: ...22 CNC 8055 CNC 8055i Returning conditions...

Page 24: ...24 CNC 8055 CNC 8055i Additional notes...

Page 26: ...26 CNC 8055 CNC 8055i Fagor documentation...

Page 448: ......

Page 464: ...464 Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X Key code...

Page 466: ...466 Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X Key code MC operator panel...

Page 467: ...Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X 467 Key code...

Page 468: ...468 Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X Key code...

Page 471: ...Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X 471 Key code 11 LCD Monitor...

Page 472: ...472 Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X Key code...

Page 478: ...478 Programming manual CNC 8055 CNC 8055i F M EN MODELS SOFT V02 2X Maintenance...

Page 479: ...Programming manual CNC 8055 CNC 8055i F SOFT V02 2X 479...

Page 480: ...480 Programming manual CNC 8055 CNC 8055i F SOFT V02 2X...

Page 481: ......