·48·

Programming manual

CNC 8055

CNC 8055i

3.

AXES AND COORDINATE

SYSTEMS

·M· & ·EN· M

ODELS

S

OFT

: V02.2

X

Co

ordin

a

te p

rogrammin

g

3.5.2

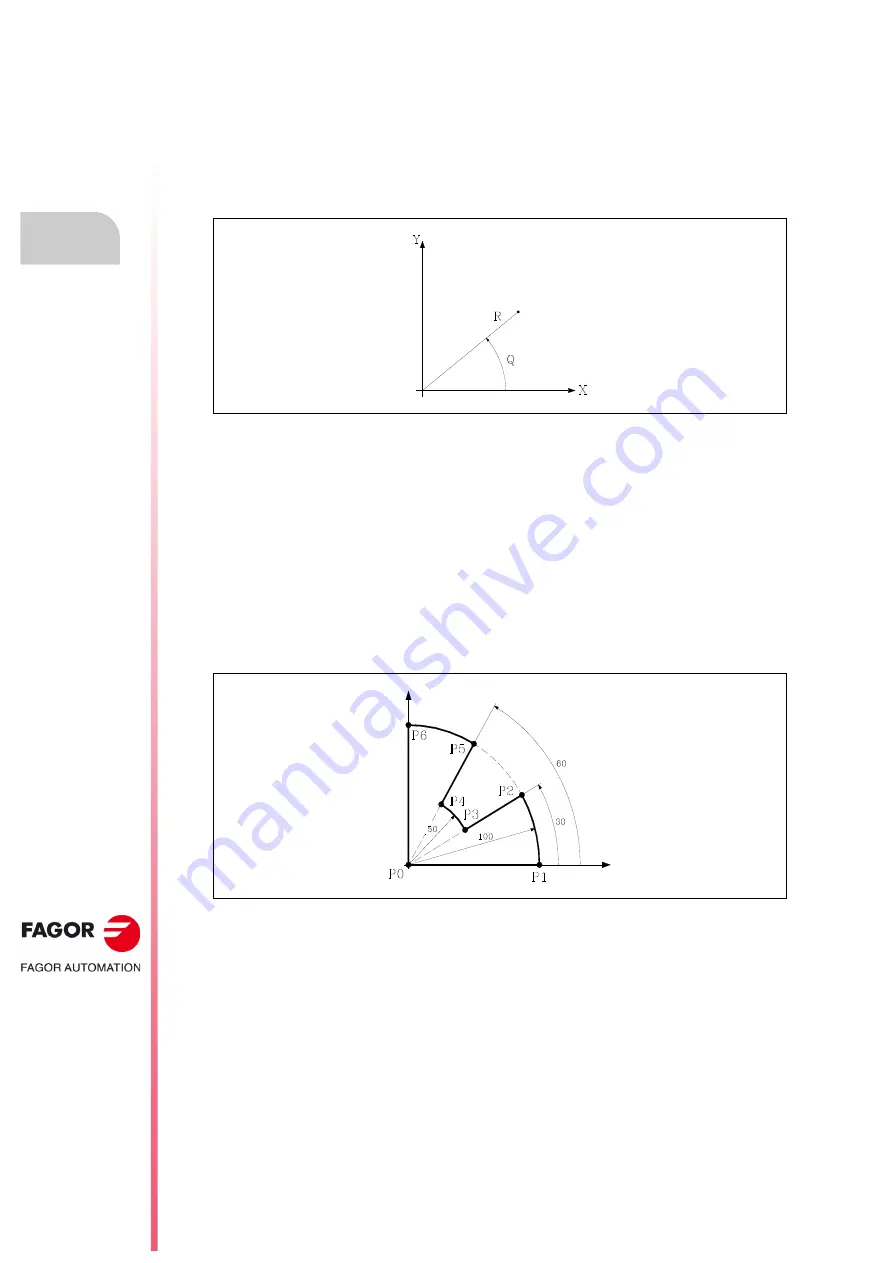

Polar coordinates

In the event of the presence of circular elements or angular dimensions, the coordinates of the

different points on the plane (2 axes at the same time), it may be easier to express them in polar

coordinates.

The reference point is called Polar Origin, and this will be the origin of the Polar Coordinate System.

A point on this system would be defined by :

• The RADIUS (R), the distance between the polar origin and the point.

• The ANGLE (Q), formed by the abscissa axis and the line which joins the polar origin with the

point. (In degrees).

The values R and Q are absolute or incremental depending on whether you are working with G90

or G91, and their programming format will be R5.5 Q±5.5. The radius value must always be positive.

The values R and Q are incremental and their programming format will be R±5.5 Q±5.5.

The R values may be negative when programming in incremental coordinates; but the resulting value

assigned to the radius must always be positive.

When programming a "Q" value greater than 360º, the module will be assumed after dividing it by

360. Thus, Q420 is the same as Q60 and Q-420 is the same as Q-60.

Programming example assuming that the Polar Origin is located at the Coordinate Origin.

Absolute coordinates:

G90

X0

Y0

; Point P0

G01

R100

Q0

; Point P1, in a straight line (G01)

G01

R50

Q30

; Point P2, in an arc (G03)

G01

R50

Q30

; Point P3, in a straight line (G01)

G03

Q60

; Point P4, in an arc (G03)

G01

R100

Q60

; Point P5, in a straight line (G01)

G03

Q90

; Point P6, in arc (G03)

G01

R0

Q90

; Point P0, in a straight line (G01)

Summary of Contents for 8055 EN

Page 1: ...CNC 8055 M EN Programming manual Ref 1711 Soft V02 2x...

Page 8: ...8 Programming manual CNC 8055 CNC 8055i SOFT V02 2X...

Page 12: ...12 CNC 8055 CNC 8055i Declaration of conformity and Warranty conditions...

Page 16: ...16 CNC 8055 CNC 8055i Version history...

Page 22: ...22 CNC 8055 CNC 8055i Returning conditions...

Page 24: ...24 CNC 8055 CNC 8055i Additional notes...

Page 26: ...26 CNC 8055 CNC 8055i Fagor documentation...

Page 448: ......

Page 464: ...464 Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X Key code...

Page 466: ...466 Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X Key code MC operator panel...

Page 467: ...Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X 467 Key code...

Page 468: ...468 Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X Key code...

Page 471: ...Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X 471 Key code 11 LCD Monitor...

Page 472: ...472 Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X Key code...

Page 478: ...478 Programming manual CNC 8055 CNC 8055i F M EN MODELS SOFT V02 2X Maintenance...

Page 479: ...Programming manual CNC 8055 CNC 8055i F SOFT V02 2X 479...

Page 480: ...480 Programming manual CNC 8055 CNC 8055i F SOFT V02 2X...

Page 481: ......