Programming manual

CNC 8055

CNC 8055i

ISO CODE

PR

OGRAMMING

5.

·M· & ·EN· M

ODELS

S

OFT

: V02.2

X

·77·

To

ol numbe

r

(T)

an

d to

ol offse

t (D)

5.6

Tool number (T) and tool offset (D)

With the "T" function, it is possible to select the tool and with the "D" function it is possible to select

the offset associated with it. When defining both parameters, the programming order is T D. For

example: T6 D17

To access, check and define these tables, refer to the operating manual.

How to use the T and D functions

• The "T" and "D" functions may be programmed alone or together as shown in the following

example:

T5 D18

Selects tool 5 and assumes the dimensions of tool offset 18.

D22

Tool 5 stays selected and it assumes the dimensions of tool offset 22.

T3

Selects tool 3 and assumes the dimensions of the offset associated with that tool.

• When having a tool magazine where the same position is occupied by more than one tool, do

the following:

Use the "T" function to refer to the magazine position and the "D" function to the dimensions

of the tool located in that position.

Thus, for example, programming T5 D23 means selecting the turret position 5 and assuming

the geometry and dimensions of tool offset 23.

Tool length and radius compensation.

The CNC looks up the "tool offset table" and assumes the tool dimensions corresponding to the

active "D" offset.

Length compensation is applied at all times, whereas radius compensation must be selected by the

operator by means of functions G40, G41, G42.

Length compensation is applied at all times, whereas tool length compensation must be selected

by the operator by means of functions G43, G44.

If there is no tool selected or D0 is defined, neither tool length nor radius compensation is applied.

For further information, refer to chapter 8 "tool compensation" in this manual..

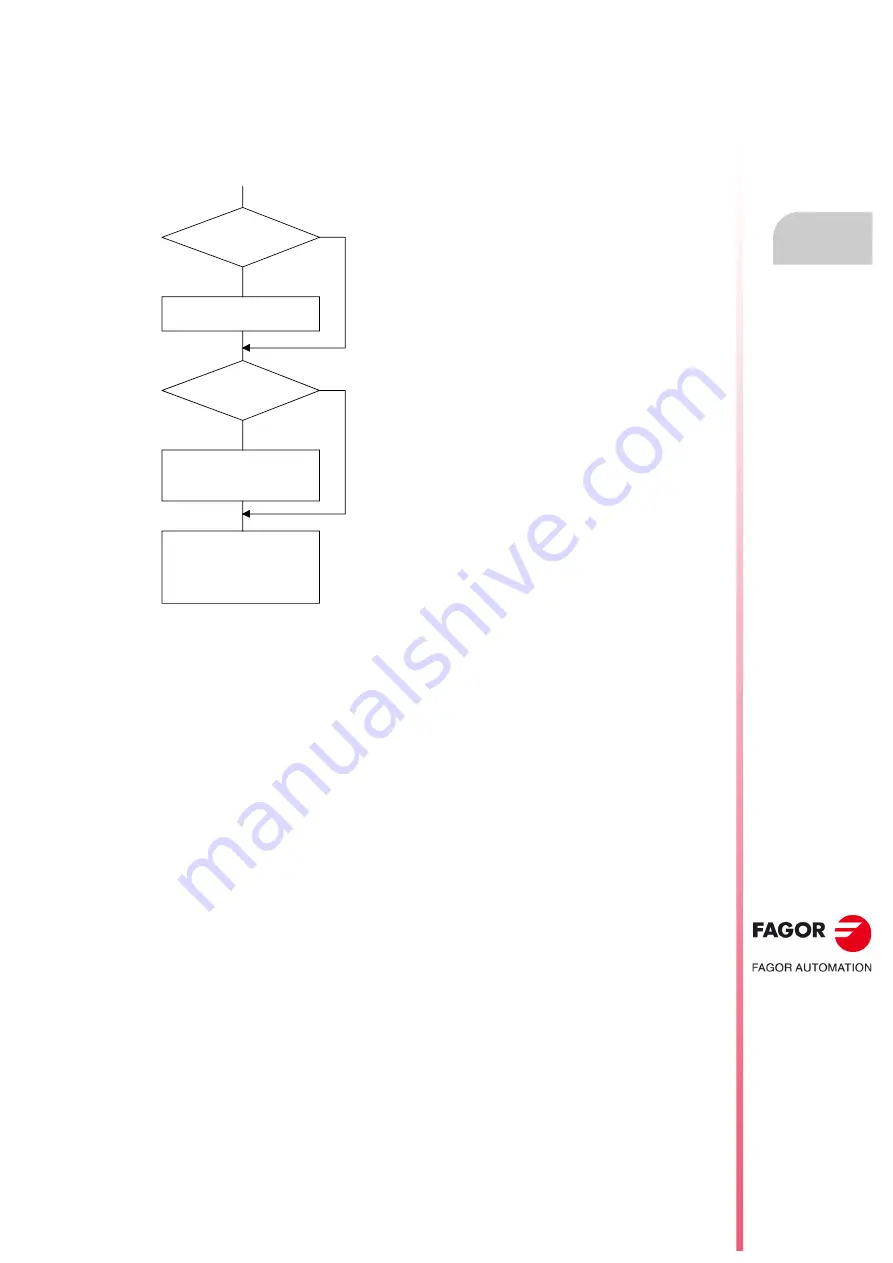

If the machine has a tool magazine, the CNC looks up the "Tool

magazine table" to know the position occupied by the selected

tool and the desired one.

If the "D" function has not be defined, it looks up the "Tool table"

to know the "D" offset associated with it.

It examines the "tool offset table" and assumes the tool

dimensions corresponding to the "D" offset.

Selects the tool

Magazine?

EZ

YES

YES

EZ

D?

The CNC takes the D

associated with the T in the

tool table

The CNC takes the

dimensions defined for the D

in the tool offset table

Summary of Contents for 8055 EN

Page 1: ...CNC 8055 M EN Programming manual Ref 1711 Soft V02 2x...

Page 8: ...8 Programming manual CNC 8055 CNC 8055i SOFT V02 2X...

Page 12: ...12 CNC 8055 CNC 8055i Declaration of conformity and Warranty conditions...

Page 16: ...16 CNC 8055 CNC 8055i Version history...

Page 22: ...22 CNC 8055 CNC 8055i Returning conditions...

Page 24: ...24 CNC 8055 CNC 8055i Additional notes...

Page 26: ...26 CNC 8055 CNC 8055i Fagor documentation...

Page 448: ......

Page 464: ...464 Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X Key code...

Page 466: ...466 Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X Key code MC operator panel...

Page 467: ...Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X 467 Key code...

Page 468: ...468 Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X Key code...

Page 471: ...Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X 471 Key code 11 LCD Monitor...

Page 472: ...472 Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X Key code...

Page 478: ...478 Programming manual CNC 8055 CNC 8055i F M EN MODELS SOFT V02 2X Maintenance...

Page 479: ...Programming manual CNC 8055 CNC 8055i F SOFT V02 2X 479...

Page 480: ...480 Programming manual CNC 8055 CNC 8055i F SOFT V02 2X...

Page 481: ......