E

XAMPLE

MANUAL

55

Editing page 50.

Access the screen customizing mode and select: [Utilities] [Editor] [Page] 50 [Enter]

Select background color:

Navy blue.

Edit the following graphic elements:

Edit the following texts:

Element

Main color

Line type

1st corner

2nd corner

Element

Main color

Line type

1st corner

2nd corner

Polyline

Light green

Thick solid

X25

Y150

X100

Y150

Line

White

Solid

X160

Y100

X295

Y100

X140

Y240

X180

Y240

Line

White

Solid

X275

Y150

X275

Y250

X220

Y150

X295

Y150

Line

White

Solid

X75

Y240

X135

Y240

Line

White

Dashed

X25

Y140

X295

Y140

Line

White

Solid

X80

Y150

X80

Y240

Line

White

Dot-dashed

X160

Y90

X160

Y260

Line

White

Solid

X100

Y145

X100

Y115

Arc

White

Solid

X130

Y217.5 X190

Y217.5

Line

White

Solid

X220

Y145

X220

Y115

Move to...

X160

Y210

Line

White

Solid

X100

Y120

X220

Y120

Line

White

Solid

X35

Y165

X35

Y120

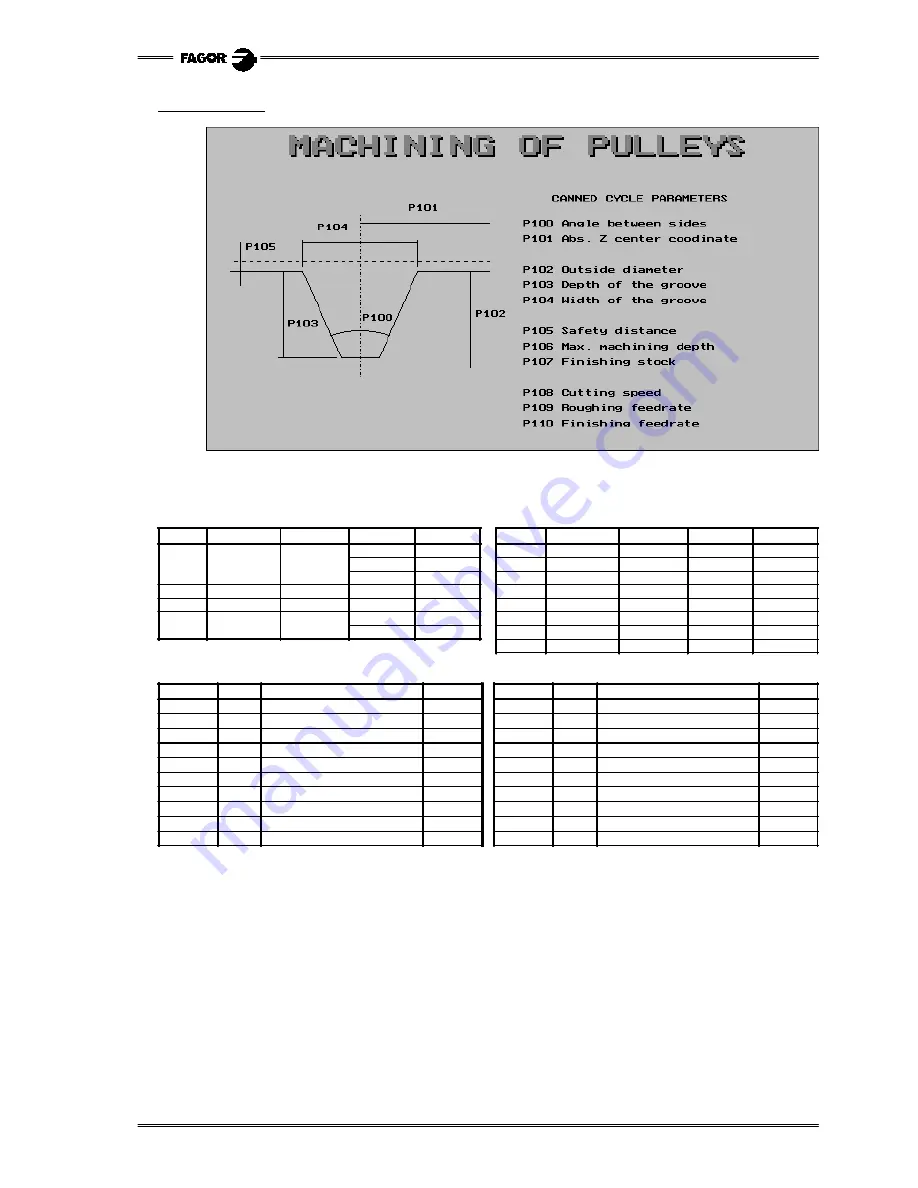

Main color

Size

Text

Position

Main color

Size

Text

Position

White

Large

MACHINING OF PULLEYS

X87

Y10

Light blue

Small

P101 Abs. Z center coordinate

X330 Y112

Red

Large

MACHINING OF PULLEYS

X85

Y8

Light blue

Small

P102 Outside diameter

X330 Y144

White

Small

P100

X162 Y194

Light blue

Small

P103 Depth of the groove

X330 Y160

White

Small

P101

X210

Y80

Light blue

Small

P104 Width of the groove

X330 Y176

White

Small

P102

X280 Y190

Light blue

Small

P105 Safety distance

X330 Y208

White

Small

P103

X84

Y200

Light blue

Small

P106 Max. machining deep

X330 Y224

White

Small

P104

X115 Y100

Light blue

Small

P107 Finishing stock

X330 Y240

White

Small

P105

X40

Y120

Light blue

Small

P108 Cutting speed

X330 Y272

White

Small

CANNED CYCLE PARAMETERS

X360

Y96

Light blue

Small

P109 Roughing feedrate

X330 Y288

Light blue

Small

P100 Angle between sides

X330

Y96

Light blue

Small

P110 Finishing feedrate

X330 Y304