SELF-TEACHING MANUAL

27

·TC· Option

THEORY ON TOOLS.

2

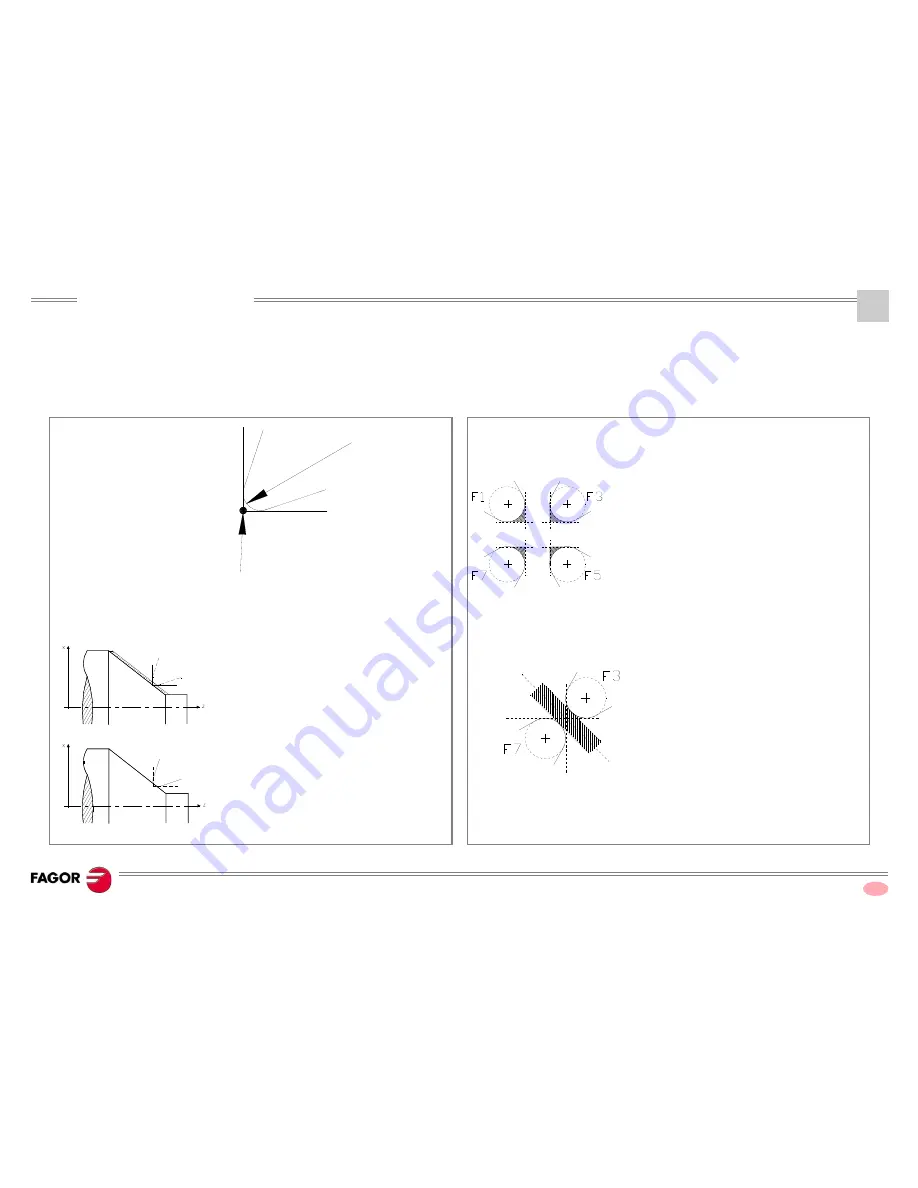

DEFECTS DUE TO WRONG LOCATION CODE DEFINITION.

The tool has a theoretical tip

and a real one.

Working with the theoretical tool tip.

Working with the real tool tip.

Theoretical tool tip.

Real tool tip.

When working with the theoretical tip, machining ridges remain. To prevent

this, the CNC works with the real tip.

To work with the theoretical tool tip, the CNC must know the calibration point

of that tool (location code) in order to be able to apply tool radius

compensation.

Knowing the location code, the CNC can

compensate for the shaded par t (radius

compensation).

If the wrong location code is entered, the error increases instead of being

compensated.

Summary of Contents for CNC 8055 TC

Page 1: ...REF 1010 8055 TC Self teaching manual CNC...

Page 6: ......

Page 16: ......

Page 21: ...SELF TEACHING MANUAL 21 TC Option THEORY ON TOOLS 2 MOST USUAL TOOL LOCATION CODES TOOL TYPES...

Page 22: ...Self teaching manual 22 TC Option THEORY ON TOOLS 2...

Page 23: ...SELF TEACHING MANUAL 23 TC Option THEORY ON TOOLS 2 MOST USUAL TOOL LOCATION CODES TOOL TYPES...

Page 24: ...Self teaching manual 24 TC Option THEORY ON TOOLS 2...

Page 30: ......

Page 52: ...Self teaching manual 52 TC Option MANUAL PRACTICE 3...

Page 54: ......

Page 70: ...Self teaching manual 70 TC Option OPERATIONS OR CYCLES 4...

Page 71: ...5 SUMMARY OF WORK CYCLES...

Page 72: ......

Page 74: ...Self teaching manual 74 TC Option SUMMARY OF WORK CYCLES 5 5 2 Turning cycle...

Page 75: ...SELF TEACHING MANUAL 75 TC Option SUMMARY OF WORK CYCLES 5 5 3 Facing cycle...

Page 84: ...Self teaching manual 84 TC Option SUMMARY OF WORK CYCLES 5 Cut off...

Page 88: ...Self teaching manual 88 TC Option SUMMARY OF WORK CYCLES 5...

Page 90: ......

Page 104: ...Self teaching manual 104 TC Option CONVERSATIONAL PART PROGRAMS 6...

Page 106: ......