Self-teaching manual

36

·TC· Option

MANUAL PRACTICE.

3

3.2 Home search.

After powering the machine up, it is recommended to home the axes just in case they have been moved while the machine

was turned off. There are two ways to do a home search.

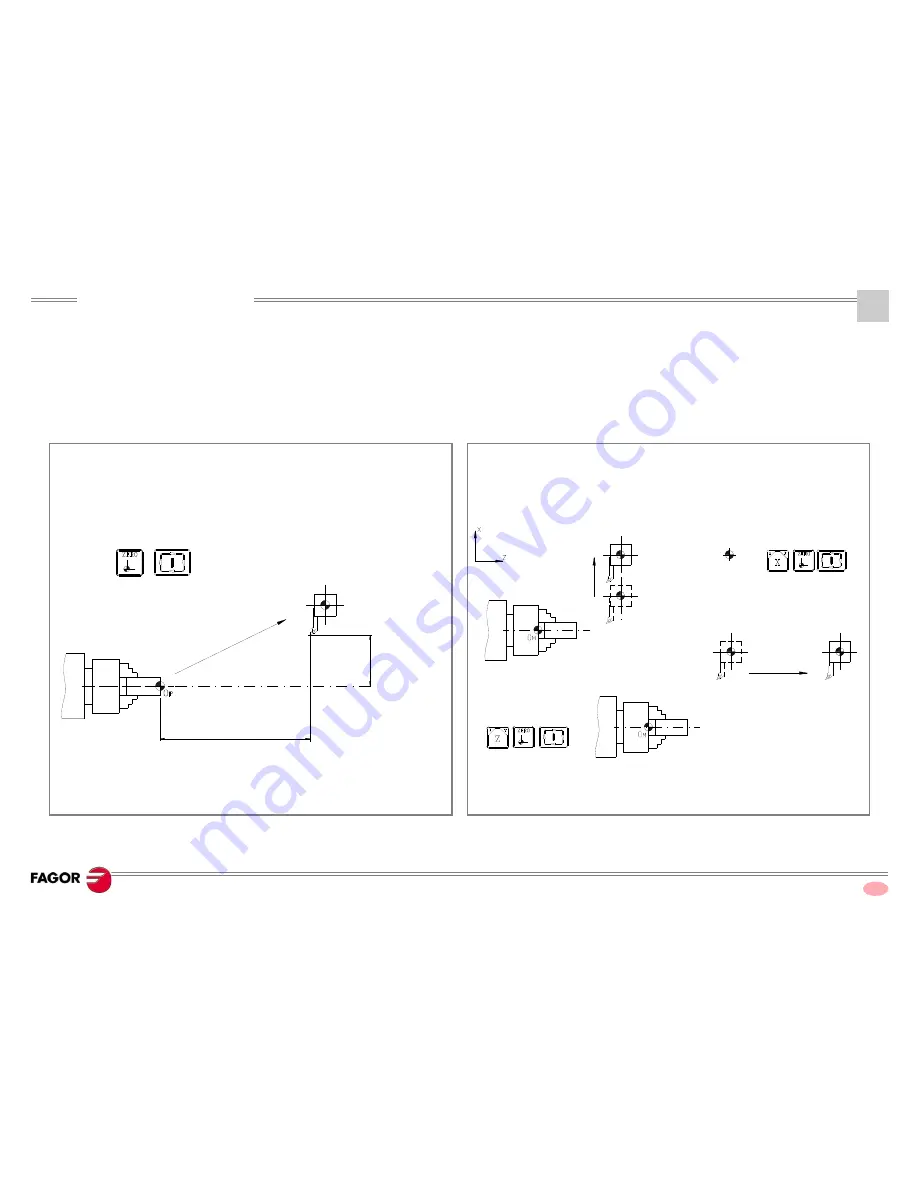

Manual home search.

Each axis is homed separately. The CNC does not keep the

part zero.

Automatic home search.

The home search is carried out on all the axes at the same

time, according to a subroutine pre-established by the

manufacturer. The CNC keeps the part zero.

Machine Z

The CNC shows the coordinates referred to part zero (O

P

)

considering the tool dimensions.

The CNC shows the coordinates referred to machine zero

(O

M

) considering the tool dimensions.

Press:

Press:

Machine X

Machine Ref.

Machine Ref.

Press:

Summary of Contents for CNC 8055 TC

Page 1: ...REF 1010 8055 TC Self teaching manual CNC...

Page 6: ......

Page 16: ......

Page 21: ...SELF TEACHING MANUAL 21 TC Option THEORY ON TOOLS 2 MOST USUAL TOOL LOCATION CODES TOOL TYPES...

Page 22: ...Self teaching manual 22 TC Option THEORY ON TOOLS 2...

Page 23: ...SELF TEACHING MANUAL 23 TC Option THEORY ON TOOLS 2 MOST USUAL TOOL LOCATION CODES TOOL TYPES...

Page 24: ...Self teaching manual 24 TC Option THEORY ON TOOLS 2...

Page 30: ......

Page 52: ...Self teaching manual 52 TC Option MANUAL PRACTICE 3...

Page 54: ......

Page 70: ...Self teaching manual 70 TC Option OPERATIONS OR CYCLES 4...

Page 71: ...5 SUMMARY OF WORK CYCLES...

Page 72: ......

Page 74: ...Self teaching manual 74 TC Option SUMMARY OF WORK CYCLES 5 5 2 Turning cycle...

Page 75: ...SELF TEACHING MANUAL 75 TC Option SUMMARY OF WORK CYCLES 5 5 3 Facing cycle...

Page 84: ...Self teaching manual 84 TC Option SUMMARY OF WORK CYCLES 5 Cut off...

Page 88: ...Self teaching manual 88 TC Option SUMMARY OF WORK CYCLES 5...

Page 90: ......

Page 104: ...Self teaching manual 104 TC Option CONVERSATIONAL PART PROGRAMS 6...

Page 106: ......