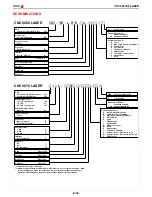

CNC 8060/70 LASER

- 6/12 -

SOFTWARE DESCRIPTIONS

Compact Flash (GB) (8070 CNC only)

It may be of 4GB, 8GB or 32 GB. It must be present in all the configurations. By default, the option with the least capacity is always

offered, the 4GB compact by default.

SOFT 4 AXES INTERPOLATION LIMIT (8070 CNC only)

It limits the number of axes that may be interpolated at the same time. When having this software option, they can interpolate a maximum

of 4 axes at the same time.

SOFT TOOL RADIUS COMP

Tool compensation allows programming the contour to be machined based on part dimensions and without taking into account the

dimensions of the tool that will be used later on. This avoids having to calculate and define the tool path depending on the radius of the

tool.

SOFT EDIT/SIMUL (Standard on all models)

It allows editing, modifying and simulating a part-program.

SOFT PROFILE EDITOR

It allows editing part profiles graphically and importing DXF files.

SOFT DIGITAL SERCOS (Standard on all models)

Sercos drive system bus.

SOFT PROBE

The CNC may have two probes; usually a tabletop probe to calibrate tools and a measuring probe to measure the part.

It also offers functions G100 to G104 for programming probing moves; but the probing canned cycles are

not

included.

SOFT C AXIS

It activates the kinematics for working with C axis and their associated machining cycles.

The 8070/60 CNC may be used with several C axis. The parameters of each spindle indicate whether it will work as a C axis or not and it

won’t be necessary to activate another axis in the machine parameters.

SOFT HSSA MACHINING SYSTEM (HSSA I) (8060 CNC only)

SOFT HSSA MACHINING SYSTEM (HSSA II) (8070 CNC only)

The acronym “HSSA” means High Speed Surface Accuracy. It is the new improved version of HSC (High Speed Cutting).

HSSA algorithm calculations make it possible to optimize high speed machining. This achieves higher cutting speeds, smoother contours,

better surface finish and higher accuracy.

This system is now offered in two levels, according to the CNC models, providing a choice between the

HSSA I

system in the CNC 8060

and the

HSSA II

system in the CNC 8070, which has more resources for faster speed.

SOFT TANDEM AXES

A tandem axis consists in two motors mechanically coupled (slaved) and making up a single transmission system (axis or spindle). This

system is normally used to move the axes on large machines.

The CNC configuration contemplates both axes of the tandem. Only an axis is programmed (the master tandem). The other one (the

slave tandem) cannot be programmed, but it is controlled by the CNC.

When activating this feature, it must be borne in mind that for each Tandem axis of the machine, another axis must be added to the whole

configuration of the machine. For example, on a large 3-axis lathe (XZ and tailstock), if the tailstock is a Tandem axis, the final purchase

order for the machine must indicate 4 axes.

SOFT SYNCHRONISM

LASER PATH COMPENSATION: This is one of the typical functionalities on CO2 laser machines, used to keep the overall laser path

constant to prevent variations in beam dispersion at the cutting point of the sheet. This feature is implemented using a special type of

synhronization.

SOFT TANGENTIAL CONTROL (8070 CNC only)

“Tangential Control” Keeps a rotary axis always in the same orientation with respect to the programmed path. The machining path is

defined in the axes of the active plane and the CNC keeps the orientation of the rotary axis along the whole path.

SOFT RTCP

The “DYNAMIC RTCP” option is a must for machining in RTCP (Rotating Tool Center Point) with 4, 5 or 6-axis interpolation.