Operating manual (MC).

CNC 8060

CNC 8065

O

PERATING

IN JO

G MODE

2.

T

ool

cal

ibratio

n

·49·

(R

EF

: 1709)

2.7.2

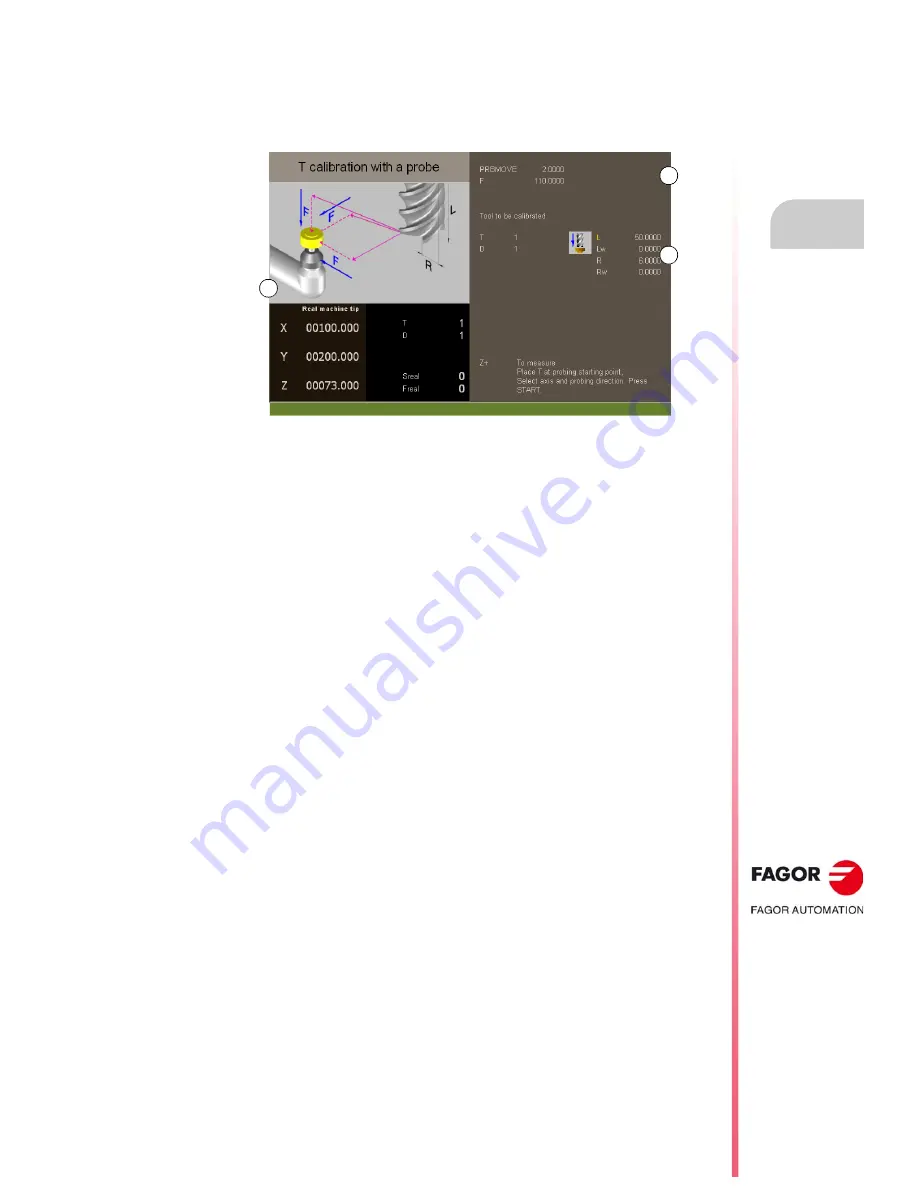

Semi-automatic calibration. Calibration with a probe

This option is only available when using a tabletop probe installed on the machine. On a

milling model, it may be used to calibrate the length and radius of the milling tools and the

offsets of the lathe tools.

A

Machine data. Position of the axes, tool and active tool offset, real spindle speed and

real feedrate of the axes.

B

Data of probing movement.

C

Necessary data for calibration.

The tool must be in the spindle. After the calibration, the wear is reset to zero.

When changing the tool data, the tool table data is updated after calibration.

Tool calibration

The calibration consists in manually approaching the tool to the probe and then command

the CNC to execute the probing movement. The CNC will move the tool on the selected axis

until touching the probe. After touching the probe, it concludes the calibration on that axis

and updates the values.

Selecting a tool

The tool and the active tool offset may be changed from the calibration mode. After defining

the new tool or tool offset in the cycle data, press [CYCLE START] and the CNC will execute

the tool change.

Bear in mind that in this calibration mode, the [CYCLE START] key has two functions. If a

new tool has been selected, it executes the tool change. If the selected tool is the active one,

pressing [CYCLE START] initiates the calibration.

Tool calibration

On milling tools, it calibrates the radius and length of the tool. After calibrating one of the two

dimensions, its wear value is reset to zero.

For the lathe tools, it calibrates the tool offsets on each axis. The offset wears are set to zero.

Validating the calibration

Use the horizontal softkey menu to select the axis and the moving direction for the calibration.

Once selected and after placing the tool in the spindle, press [CYCLE START] to start the

calibration. The tool will move in the indicated direction until touching the probe and it will

then conclude the calibration updating the tool data with the measured values.

Once the tool has been calibrated, the CNC shows a message proposing to press [START]

so the CNC assumes the new values of the offset. When pressing [START] while this

message is displayed, the CNC assumes the new values of the offset; if the message is not

displayed, pressing [START] executes the probing movement again.

B

A

C

Summary of Contents for CNC 8060

Page 1: ...Ref 1709 8060 8065 CNC Operating manual MC...

Page 8: ...BLANK PAGE 8...

Page 14: ...BLANK PAGE 14...

Page 16: ...BLANK PAGE 16...

Page 18: ...BLANK PAGE 18...

Page 22: ...BLANK PAGE 22...

Page 24: ...BLANK PAGE 24...

Page 26: ...BLANK PAGE 26...

Page 169: ...Operating manual MC CNC 8060 CNC 8065 169 User notes REF 1709...

Page 170: ...Operating manual MC CNC 8060 CNC 8065 170 User notes REF 1709...

Page 171: ...Operating manual MC CNC 8060 CNC 8065 171 User notes REF 1709...