137

Note: The parameters indicated between angular brackets are

optional.

Cycle

Meaning

#PROBE 1

Tool calibration (dimensions and wear).

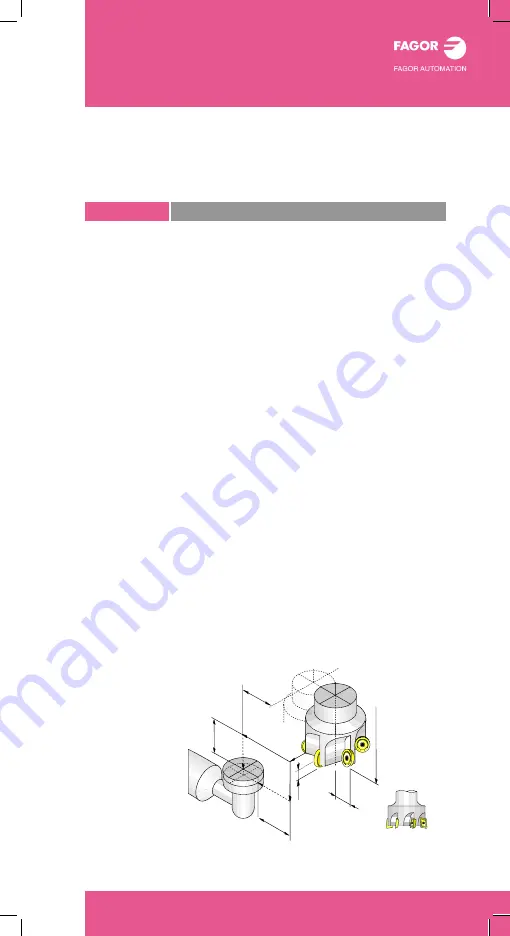

#PROBE 1 B [I] [J] F [K] [S] [N] [D] [E]

[L] [M] [C] [X U Y V Z W]

B: Safety distance

I: Dimension of the tool to be calibrated (if

I0, length on the axis; if I1, length at one

end; if I2, radius; if I3, radius and length)

J: Type of operation (if J0, calibration; if J1,

wear measurement)

F: Probing feedrate

K: Side of the probe being used (if K0, X+

side; if K1, X- side; if K2, Y+ side; if K3,

Y- side)

S: Speed and turning direction of the tool

N: Number of edges to be measured (if N=0

or when not programmed, one turning

m e a s u r e m e n t ; i f N =+ n , e x a c t

measurement of the first edge and the rest

a r e e q u i d i s t a n t , i f N = - n , e x a c t

measurement of the n edges)

D: Distance from the probing point to the tool

shaft

E: Distance from the probing point to the tool

base

L: Maximum length wear allowed

M:Maximum radius wear allowed

C: Behavior when exceeding the maximum

wear

X..W: Tabletop probe position

B

B

L

R

D

N

D

z

MEASURING AND

CALIBRATION CYCLES (M)

Summary of Contents for CNC 8060

Page 1: ...CNC 8060 65 User quick reference Ref 1906...

Page 44: ...Work modes 44...

Page 64: ...ISO language 64...

Page 102: ...ISO canned cycles T 102...

Page 128: ...Conversational cycles M 128...

Page 136: ...Conversational cycles T 136...

Page 150: ...Measuring and calibration cycles T 150...

Page 169: ......