ISO canned cycles (M)

70

G86

*

* Boring canned cycle.

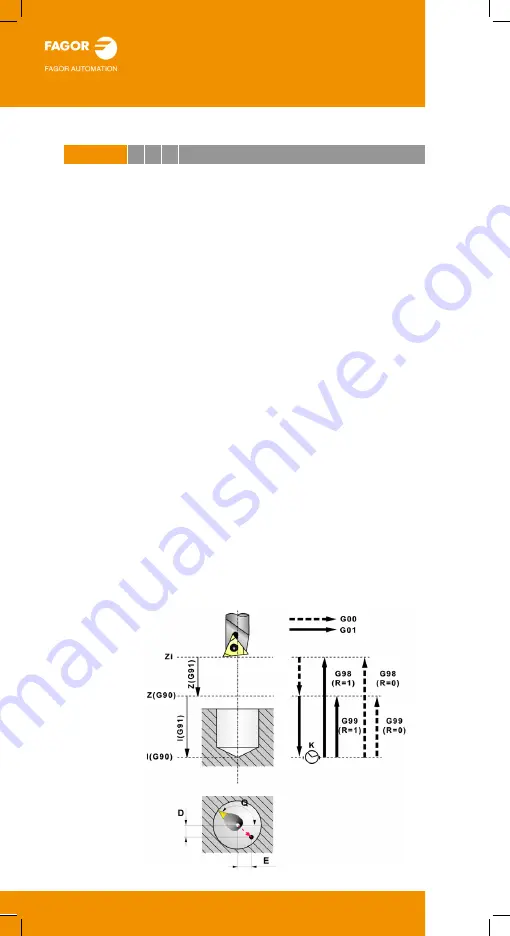

G86 [Z] I [K] [R] [A] Q D E

Z: Reference plane

I: Boring depth

K: Dwell in seconds at the bottom of the hole

(default =0)

R: Type of withdrawal, when parameter A is not

programmed. R0: Rapid feedrate withdrawal

(G0) with the spindle stopped (default value);

R1: Withdraw at work feedrate (G1)

A: Spindle behavior when going into the hole and

coming out of it

A0: The tool goes into the hole turning and

comes out stopped

A1: The tool goes into the hole stopped and

comes out turning

When not programmed, the tool goes into the

h o l e a n d c o m e s o u t t u r n i n g. W h e n

programming A0 or A1, define the spindle

stop with parameters Q, D and E.

Q: Spindle position, in degrees, to separate the

cutter from the wall of the hole

When programming A0 or A1, this parameter

sets the tool orientation and parameters D

and E set the distance the tool withdraws off

(away from) the walls of the hole.

D: Distance to withdraw the cutter off the wall of

the hole along the abscissa axis

E: Distance to withdraw the cutter off the wall of

the hole along the ordinate axis

Function

M D

V

Meaning

Summary of Contents for CNC 8060

Page 1: ...CNC 8060 65 User quick reference Ref 1906...

Page 44: ...Work modes 44...

Page 64: ...ISO language 64...

Page 102: ...ISO canned cycles T 102...

Page 128: ...Conversational cycles M 128...

Page 136: ...Conversational cycles T 136...

Page 150: ...Measuring and calibration cycles T 150...

Page 169: ......