ISO canned cycles (M)

77

Multiple machining (M model)

Parameters P, Q, R, S, T, U and V are optional parameters that

may be used in any type of multiple positioning. Thus,

programming "P7" means that no machining operation takes

place at point 7. Programming "Q10.013" means that no

machining takes place at points 10, 11, 12 and 13. If these

parameters are not programmed, the CNC understands that it

must perform machining at all the points along the programmed

path.

Function

M D

V

Meaning

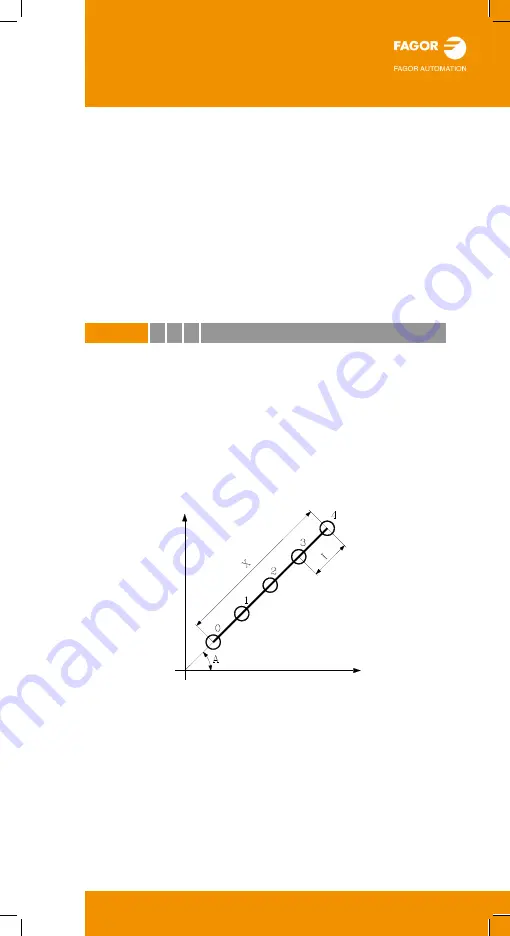

G160

* Multiple machining in a straight line.

G160 A X I K [P] [Q] [R] [S] [T] [U] [V]

A: Angle, in degrees of the tool path with respect

to the abscissa axis (default = 0).

X: Length of the machining path

I: Step between machining operations

K: Total number of machining operations in the

section, including that of the machining

definition point

Note: when defining the machining operation,

only two of parameters X, I and K are required.

Summary of Contents for CNC 8060

Page 1: ...CNC 8060 65 User quick reference Ref 1906...

Page 44: ...Work modes 44...

Page 64: ...ISO language 64...

Page 102: ...ISO canned cycles T 102...

Page 128: ...Conversational cycles M 128...

Page 136: ...Conversational cycles T 136...

Page 150: ...Measuring and calibration cycles T 150...

Page 169: ......