Quick reference

18

(S

OFT

03.1

X

)

TURNING CANNED CYCLES

Preparatory (G), technological (F, S) and auxiliary (M, H) functions must be defined before the canned cycle.

Functions G98, G99 and the positioning move to the machining point must also be programmed before.

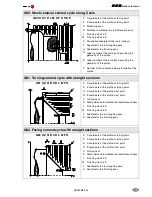

G66. Pattern repeat canned cycle

G66 X Z I C A L M H S E P

X

X coordinate of the profile's starting point.

Z

Z coordinate of the profile's starting point.

I

Remaining stock.

C

Machining pass.

A

Defines the main machining axis:

• "A"=0: Z is the main axis.

• "A"=1: X is the main axis.

L

Finishing stock in X.

M

Finishing stock in Z.

H

Feedrate for the finishing pass.

S

Label number of the first block describing the

geometry of the profile.

E

Label number of the last block describing the

geometry of the profile.

P

Number of the subroutine where that defines the

profile.

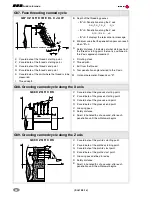

G68. Stock removal cycle along X axis

G68 X Z C D L M K F H S E P

X

X coordinate of the profile's starting point.

Z

Z coordinate of the profile's starting point.

C

Machining pass.

D

Safety distance to withdraw the tool after each pass.

L

Finishing stock in X.

M

Finishing stock in Z.

K

Penetration feedrate for the roots (valleys).

F

Feedrate for the last roughing pass.

H

Feedrate for the finishing pass.

S

Label number of the first block describing the

geometry of the profile.

E

Label number of the last block describing the

geometry of the profile.

P

Number of the subroutine where that defines the

profile.

Summary of Contents for CNC 8070

Page 1: ...Quick reference SOFT 03 1X REF 0706 CNC 8070...

Page 44: ......