Hardware configuration.

CNC 8070

13.

OP-PANEL /

OP-PANEL+SPDL R

A

TE.

Hardw

are fu

ncti

ona

lities.

·246·

(R

EF

: 1911)

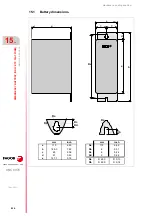

24 V DC voltage supply.

Handwheel connection.

Connector data.

Number of poles.

3.

Pitch.

7.62 mm.

Connection technique.

Screw connection.

Minimum/maximum tightening torque. 0.5 / 0.6 Nm.

Minimum/maximum section.

0.2 / 2.5 mm².

Minimum/maximum AWG section.

24 / 12.

Rated current In.

12 A.

Cable data.

Length to be stripped.

7 mm.

"13.5 Power supply for the module."

Connector data.

Number of poles.

10.

Pitch.

3.5 mm.

Connection technique.

Spring connection.

Minimum/maximum section.

0.2 / 1.5 mm².

Minimum/maximum AWG section.

24 / 16.

Rated current In.

8 A.

Cable data.

Length to be stripped.

7 mm.

Plug-in part. 3-pole Phoenix-type combicon connector (7.62 mm

pitch).

Pin

Signal.

Function.

1

Chassis.

2

GND

0 V reference signal.

3

+24 V

Power supply.

1

Plug-in part. 10-pole Phoenix-contact minicombicon connector

(3.5 mm pitch).

Pin.

Signal.

Function.

1

+5 V

5 V DC voltage supply.

2

- - -

- - -

3

- - -

- - -

4

MPG3-B

B signal of the third handwheel.

5

MPG3-A

A signal of the third handwheel.

6

MPG2-B

B signal of the second handwheel.

7

MPG2-A

A signal of the second handwheel.

8

MPG1-B

B signal of the first handwheel.

9

MPG1-A

A signal of the first handwheel.

10

GND

Power supply.

Cable shields must be connected to the ground plate. See

Summary of Contents for CNC 8070

Page 1: ...Ref 1911 8070 CNC Hardware configuration...

Page 8: ...BLANK PAGE 8...

Page 14: ...BLANK PAGE 14...

Page 18: ...BLANK PAGE 18...

Page 22: ...BLANK PAGE 22...

Page 24: ...BLANK PAGE 24...

Page 26: ...BLANK PAGE 26...

Page 28: ...Hardware configuration CNC 8070 1 PREVIOUS INFORMATION 28 REF 1911...

Page 94: ...Hardware configuration CNC 8070 6 CENTRAL UNIT MONITOR Q7 A PLATFORM 94 REF 1911 C70 15AT...

Page 273: ...Hardware configuration CNC 8070 273 User notes REF 1911...

Page 274: ...Hardware configuration CNC 8070 274 User notes REF 1911...

Page 275: ...Hardware configuration CNC 8070 275 User notes REF 1911...