Hardware configuration.

CNC 8070

3.

HEAT DISSIPATION. CENTRA

L UNIT (CPU)

EN

CLOSURE (ETX

Hea

t di

ssi

pation

mod

els.

·42·

(R

EF

: 1911)

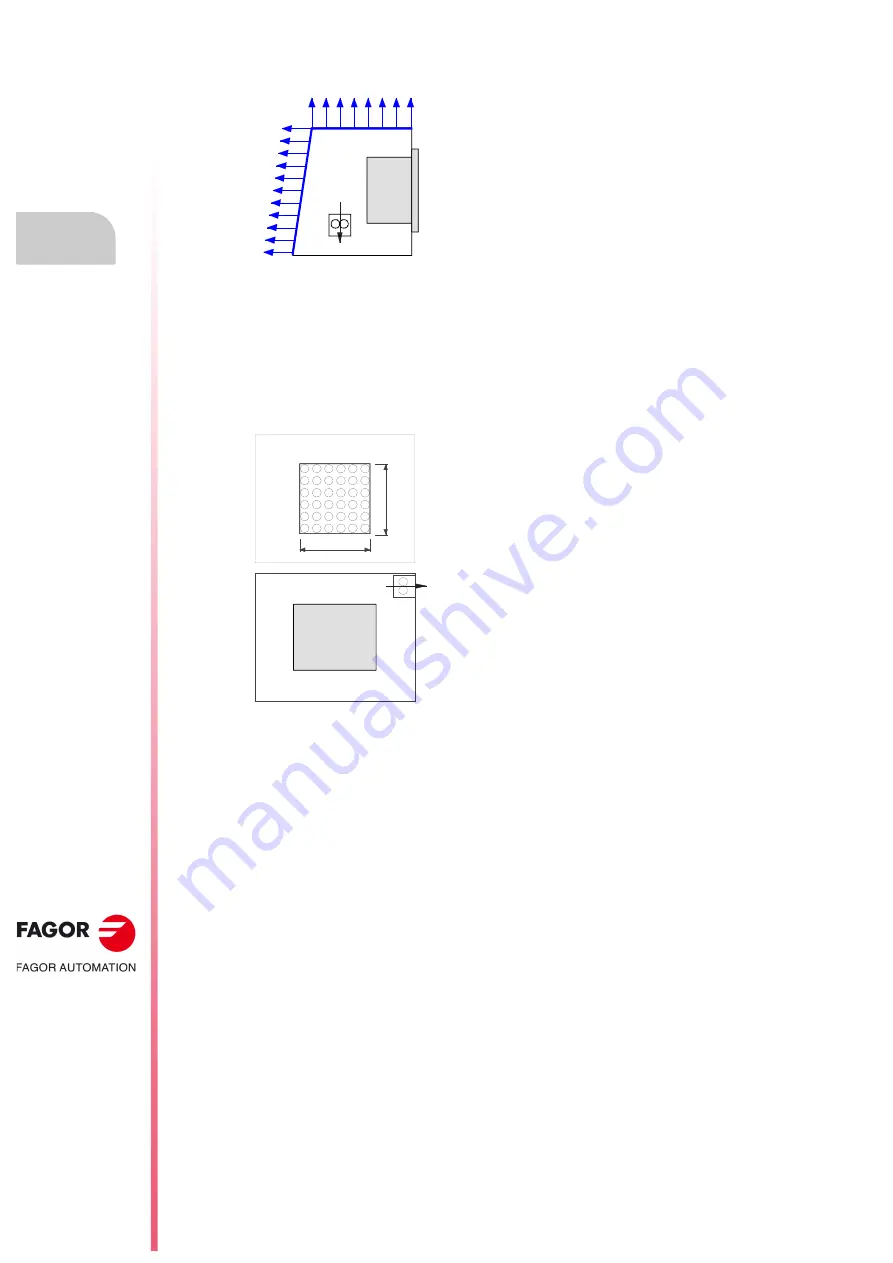

Fan whose air flow Q = 102 m³/h facing down.

Heat dissipation by air flow to the outside using a fan.

Heat dissipation by forced convection with hot air flow to the outside using a fan and ambient

air intake through the holes located at the bottom of the enclosure.

For this case, the volume of air flow is calculated necessary to evacuate the heat generated

inside the enclosure. The fan's air flow is calculated according to the power dissipated by

the CNC and the fan itself as well as the inside and outside temperatures.

Bear in mind that this air flow through the unit extracts hot air to the outside, but it allows

dirt into the enclosure. Thus, a filter should be installed to maintain the ambient conditions

allowed.

Unpainted surface.

Surface with smooth metallic enamel.

A

P

7,5

T

------------------

=

A

P

9,8

T

------------------

=

Ti

Ta

A

P

Unpainted surface.

V

3,8 P

T

---------------

=

40

40

Ø6

Summary of Contents for CNC 8070

Page 1: ...Ref 1911 8070 CNC Hardware configuration...

Page 8: ...BLANK PAGE 8...

Page 14: ...BLANK PAGE 14...

Page 18: ...BLANK PAGE 18...

Page 22: ...BLANK PAGE 22...

Page 24: ...BLANK PAGE 24...

Page 26: ...BLANK PAGE 26...

Page 28: ...Hardware configuration CNC 8070 1 PREVIOUS INFORMATION 28 REF 1911...

Page 94: ...Hardware configuration CNC 8070 6 CENTRAL UNIT MONITOR Q7 A PLATFORM 94 REF 1911 C70 15AT...

Page 273: ...Hardware configuration CNC 8070 273 User notes REF 1911...

Page 274: ...Hardware configuration CNC 8070 274 User notes REF 1911...

Page 275: ...Hardware configuration CNC 8070 275 User notes REF 1911...