Hardware configuration.

CNC 8070

CENTRAL

UNIT + MONITO

R (ETX PLATFORM).

5.

Conn

ecti

ons.

·87·

(R

EF

: 1911)

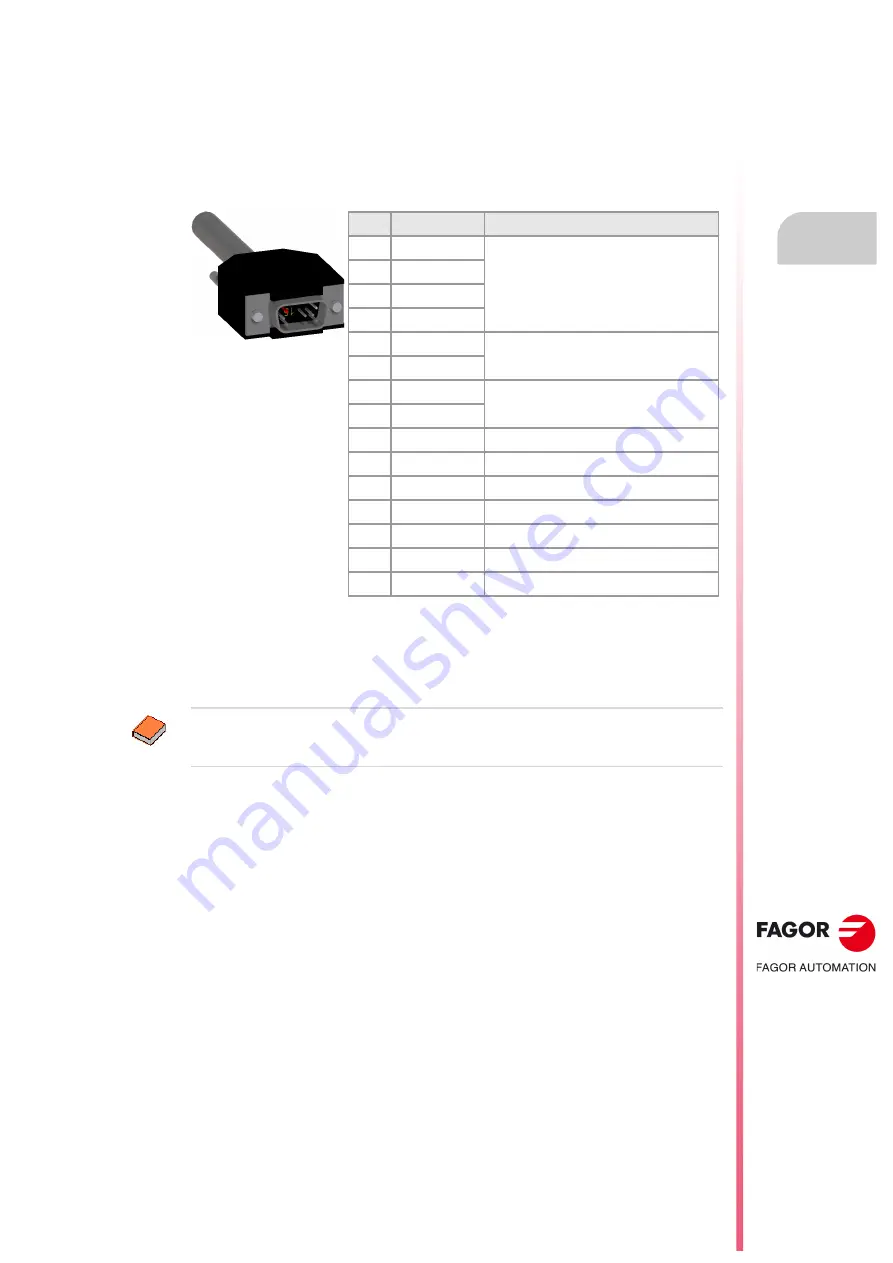

5.12.5 Feedback connection.

The central unit has 2 feedback inputs, valid for TTL and differential TTL signals.

Connector pinout.

Plug-in part. 15-pin male SUB-D HD type connector.

Cable characteristics.

We recommend to run the feedback cables as far away as possible from the power cables

of the machine.

The cable being used must have overall shield. The cable shield must be connected to the

metallic hood at each end. The unshielded portion of the wires of an unshielded cable cannot

be longer than 75 mm.

(*) Pin ·15· is offered for compatibility. We recommend to connect the

cable shield to the connector housing at both ends.

Pin.

Signal.

Description.

1

A

Feedback signals.

2

/A

3

B

4

/B

5

I0

Reference signals.

6

/I0

7

AL

Feedback alarm.

8

/AL

9

+5 V DC

Voltage supply for the feedback system.

10

- - -

11

GND

0 V reference signal.

12

- - -

13

- - -

14

- - -

15

Chassis(*)

Shield.

1 ... 5

6 ... 10

11 ... 15

Fagor Automation offers a wide range of cables and extension cables to connect the feedback systems

to the CNC. The cable characteristics , as well as its length, depend on the type of feedback being

used. Refer to our catalog for further information.

Summary of Contents for CNC 8070

Page 1: ...Ref 1911 8070 CNC Hardware configuration...

Page 8: ...BLANK PAGE 8...

Page 14: ...BLANK PAGE 14...

Page 18: ...BLANK PAGE 18...

Page 22: ...BLANK PAGE 22...

Page 24: ...BLANK PAGE 24...

Page 26: ...BLANK PAGE 26...

Page 28: ...Hardware configuration CNC 8070 1 PREVIOUS INFORMATION 28 REF 1911...

Page 94: ...Hardware configuration CNC 8070 6 CENTRAL UNIT MONITOR Q7 A PLATFORM 94 REF 1911 C70 15AT...

Page 273: ...Hardware configuration CNC 8070 273 User notes REF 1911...

Page 274: ...Hardware configuration CNC 8070 274 User notes REF 1911...

Page 275: ...Hardware configuration CNC 8070 275 User notes REF 1911...