Hardware configuration.

CNC 8070

HORIZONTAL KEYB

/ HO

RIZONTAL KEYB+MOUSE.

10.

Bus CAN

(CAN

fag

or/CANope

n protocols).

·215·

(R

EF

: 1911)

10.7.1 Identification of the modules at the bus.

Each one of the elements integrated into the CAN bus is identified by its address or node

number. The CNC must always occupy position "0" and the rest of the elements of the bus

will occupy consecutive positions starting with "1". The node address or number also sets

the priority of the group within the bus; the lower the number the higher the priority. We

recommend to set the priority of the groups as follows (from highest to lowest).

• The groups that have the feedback inputs.

• The groups that have analog inputs and outputs.

• The groups that have digital inputs and outputs.

• The keyboard and jog panel.

In order for any change in the identification of the module to take effect, the CNC must be

restarted and turn off/on the corresponding module; however, we recommend to change the

address while the modules and the CNC are off.

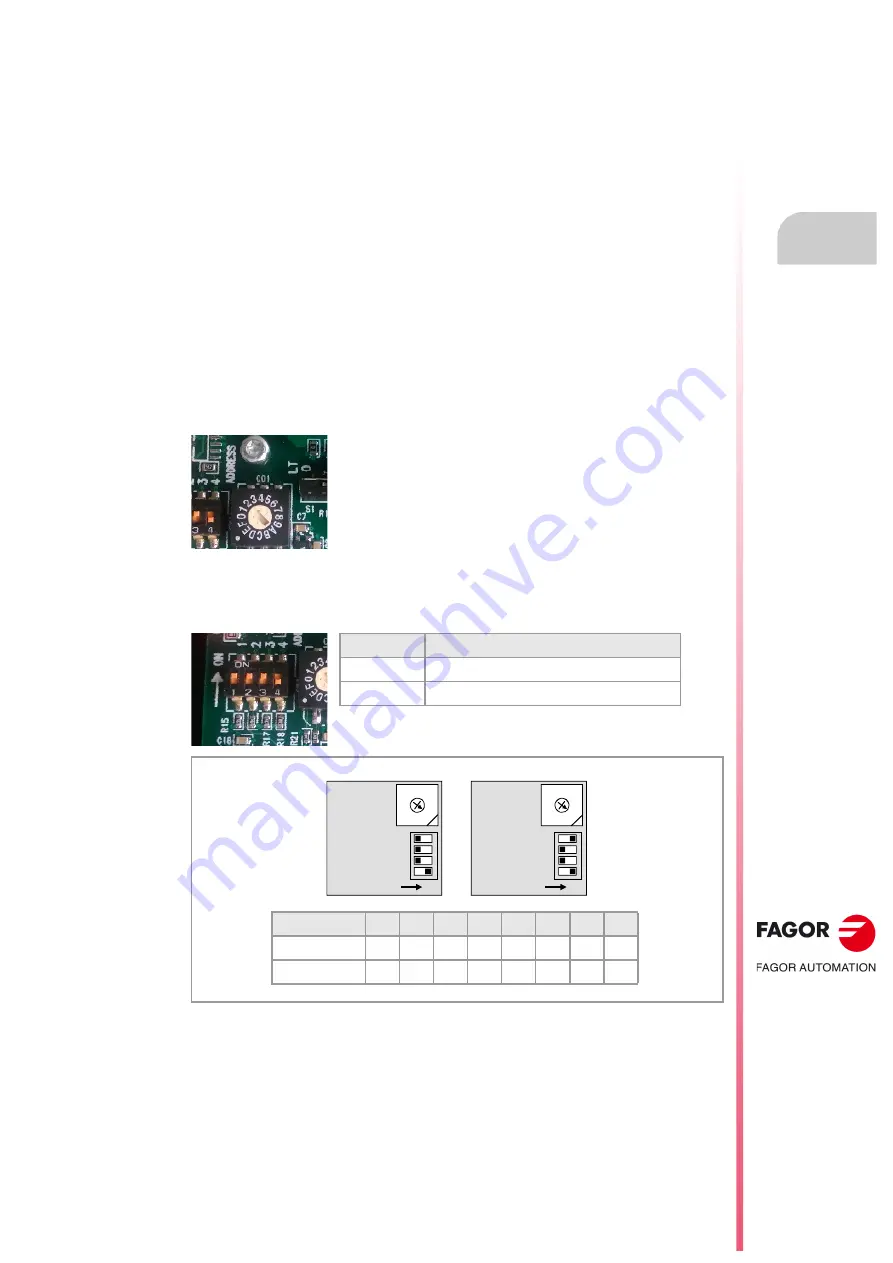

Configuring the address (node number).

Address (node) of the element within the bus (0-15).

Address (node) of the element within the bus (16-31).

Switch ·4· of the DIP switch selects the positions or elements integrated in the CAN bus may

be expanded up to 32.

Each one of the elements integrated into the CAN bus is identified

by the 16-position rotary switch (0-15) "Address" (also referred to

as "Node_Select").

DS ·4·

Address (node) of the element.

off

Positions 0-15 within the bus.

on

Positions 16-31 within the bus.

ADDRESS

0

1

2

3

···

13

14

15

DS4 = 0

0

1

2

3

···

13

14

15

DS4 = 1

16

17

18

19

···

29

30

31

4

0F

E

D

C

B

A

9

8

7 6 5 3 2

1

ID4 = 0

ADDRESS = 2

ADDRESS = 18

ON

ID3

ID2

ID1

4

0F

E

D

C

B

A

9

8

7 6 5 3 2

1

ADDRESS = 2

ID4 = 1

ON

ID3

ID2

ID1

ADDRESS = 2

Summary of Contents for CNC 8070

Page 1: ...Ref 1911 8070 CNC Hardware configuration...

Page 8: ...BLANK PAGE 8...

Page 14: ...BLANK PAGE 14...

Page 18: ...BLANK PAGE 18...

Page 22: ...BLANK PAGE 22...

Page 24: ...BLANK PAGE 24...

Page 26: ...BLANK PAGE 26...

Page 28: ...Hardware configuration CNC 8070 1 PREVIOUS INFORMATION 28 REF 1911...

Page 94: ...Hardware configuration CNC 8070 6 CENTRAL UNIT MONITOR Q7 A PLATFORM 94 REF 1911 C70 15AT...

Page 273: ...Hardware configuration CNC 8070 273 User notes REF 1911...

Page 274: ...Hardware configuration CNC 8070 274 User notes REF 1911...

Page 275: ...Hardware configuration CNC 8070 275 User notes REF 1911...