Hardware configuration.

CNC 8070

16.

CNC-FPS. FAGOR-U

P

S (Q

7

-A PLATFORM

ONLY).

UPS Con

nection

Di

agram.

·262·

(R

EF

: 1911)

16.5

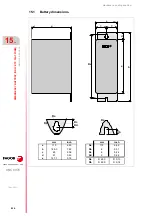

UPS Connection Diagram.

Jumper terminals.

• The R1-R2 terminals are jumpered at the factory: to connect the UPS to the CNC, the

jumper must be removed.

• The 13-23-33-24V terminals are jumpered at the factory: to connect the UPS to the CNC,

there is no need to remove the jumper.

Connection to the CNC and to the power supply.

The R1-R2 connector of the UPS is a free of potential relay. Both signals can go to any

DISSABLE_BAT pin of the CNC (never both signals to the same pin).

Cable characteristics.

Maintain.

Remove.

I65

BAT_MODE

DISABLE_BAT

DISABLE_BAT

UPS.

CNC.

A22

24 V

GND

+

–

Output.

24 V power supply.

+

–

+

–

Output.

Input.

34

R1

R2

24

14

Cable data.

Minimum/maximum tightening torque.

0.5 / 0.6 Nm.

Minimum/maximum section.

0.2 / 2.5 mm².

Minimum/maximum AWG section.

24 / 12.

Length to be stripped.

(use ferrules on flexible wires/cables).

7 mm.

Summary of Contents for CNC 8070

Page 1: ...Ref 1911 8070 CNC Hardware configuration...

Page 8: ...BLANK PAGE 8...

Page 14: ...BLANK PAGE 14...

Page 18: ...BLANK PAGE 18...

Page 22: ...BLANK PAGE 22...

Page 24: ...BLANK PAGE 24...

Page 26: ...BLANK PAGE 26...

Page 28: ...Hardware configuration CNC 8070 1 PREVIOUS INFORMATION 28 REF 1911...

Page 94: ...Hardware configuration CNC 8070 6 CENTRAL UNIT MONITOR Q7 A PLATFORM 94 REF 1911 C70 15AT...

Page 273: ...Hardware configuration CNC 8070 273 User notes REF 1911...

Page 274: ...Hardware configuration CNC 8070 274 User notes REF 1911...

Page 275: ...Hardware configuration CNC 8070 275 User notes REF 1911...