Installation

312

8.

INSTAL

LAT

ION

C

onne

cti

on

of the

con

trol

a

nd

communica

tions

signa

ls

304

DDS

HARDWARE

Ref.1310

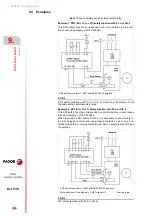

Line terminating resistor (RT)

After connecting the modules, make sure that the external elements con-

nected to the bus have their terminating resistor RT activated.

The CNC (or the ESA panel), located at the end of the bus always has the

line terminating resistor activated. See figure

.

Transmission speed selection

From version 07.02, 08.01 and newer, the drive may have a CAN card ca-

pable of transmitting data at 1 MB, 800 kBd or 500 kBd.

In this data transmission, each drive can receive and transmit 4 IDns

(CAN identifiers) or 4 Words (64 bits) through the fast channel.

The communication speed between all the drives being governed by the

CNC in the CAN bus is selected by hardware using the “boot” button on

top of the CANcard connector. See figure

The parameter associated with the communication speed selection of the

CAN bus is QP11 and every time a speed is selected, this parameter is as-

sociated the corresponding value. See table

that shows the possi-

ble baudrate values that will be shown on the drive display. Chapter 12 of

the “dds-software” manual explains the meaning of parameter QP11.

Change of transmission speed

In an initial state (0 state), the display shows certain information that lacks

interest for the operator, except the software version, errors and warnings if

there are any. Keeping the “boot” button pressed for 3 seconds (long push)

it switches to a new state (state 1) that is used for selecting the communica-

tion speed and the display shows the speed currently selected.

In this state 1, every time this button is pressed for less than 0.8 seconds

(short push), the display shows the next communication speed value that

may be selected. Hence, apply several short pushes until the desired

speed is displayed.

NOTE.

The RT switch (located under the CAN connector) of the last drive

(usually the one farthest away from the CNC) must be activated (position

1

switch down) and the rest of the drives connected to the bus must be

deactivated (position 0

switch up).

NOTE.

This card is not compatible with drive software versions older

than 07.02. See chapter

NOTE.

Consequently, the serial connection will no longer be necessary

to select the transmission speed.

F. H8/36

Location of the “BOOT” button at the drive.

Node selector

“BOOT” BUTTON

X5

Status display

X6

1

1

9

CAN connector

Line terminating resistor

activating switch

RS-232 line connector

Summary of Contents for DDS

Page 1: ...DRIVE DDS Hardware manual Ref 1310...

Page 6: ...I 6 DDS HARDWARE Ref 1310...

Page 9: ......

Page 10: ......

Page 11: ......

Page 12: ......

Page 16: ...16 Ref 1310 DDS HARDWARE...

Page 30: ...1 DESCRIPTION 30 Description DDS HARDWARE Ref 1310...

Page 94: ...2 POWER SUPPLIES 94 Power supplies DDS HARDWARE Ref 1310...

Page 188: ...3 DRIVE MODULES 188 Drive modules DDS HARDWARE Ref 1310...

Page 204: ...4 AUXILIARY MODULES 204 Auxiliary modules DDS HARDWARE Ref 1310...

Page 232: ...SELECTING CRITERIA 5 232 Selection criteria DDS HARDWARE Ref 1310...

Page 266: ...7 CABLES 266 Cables DDS HARDWARE Ref 1310...

Page 312: ...8 INSTALLATION 312 Installation DDS HARDWARE Ref 1310...

Page 326: ...9 FUNCTIONAL SAFETY 326 Functional safety DDS HARDWARE Ref 1310...

Page 354: ...10 CONNECTION DIAGRAMS 354 Connection diagrams DDS HARDWARE Ref 1310...

Page 378: ...12 SALES REFERENCES 378 Sales references DDS HARDWARE Ref 1310...

Page 384: ...13 COMPATIBILITY 384 Compatibility DDS HARDWARE Ref 1310...

Page 385: ......