Sales references

378

12.

SALES REFERENCES

Re

fe

re

nces of

synch

ro

nou

s servo motors

366

DDS

HARDWARE

Ref.1310

12.1

References of synchronous servo motors

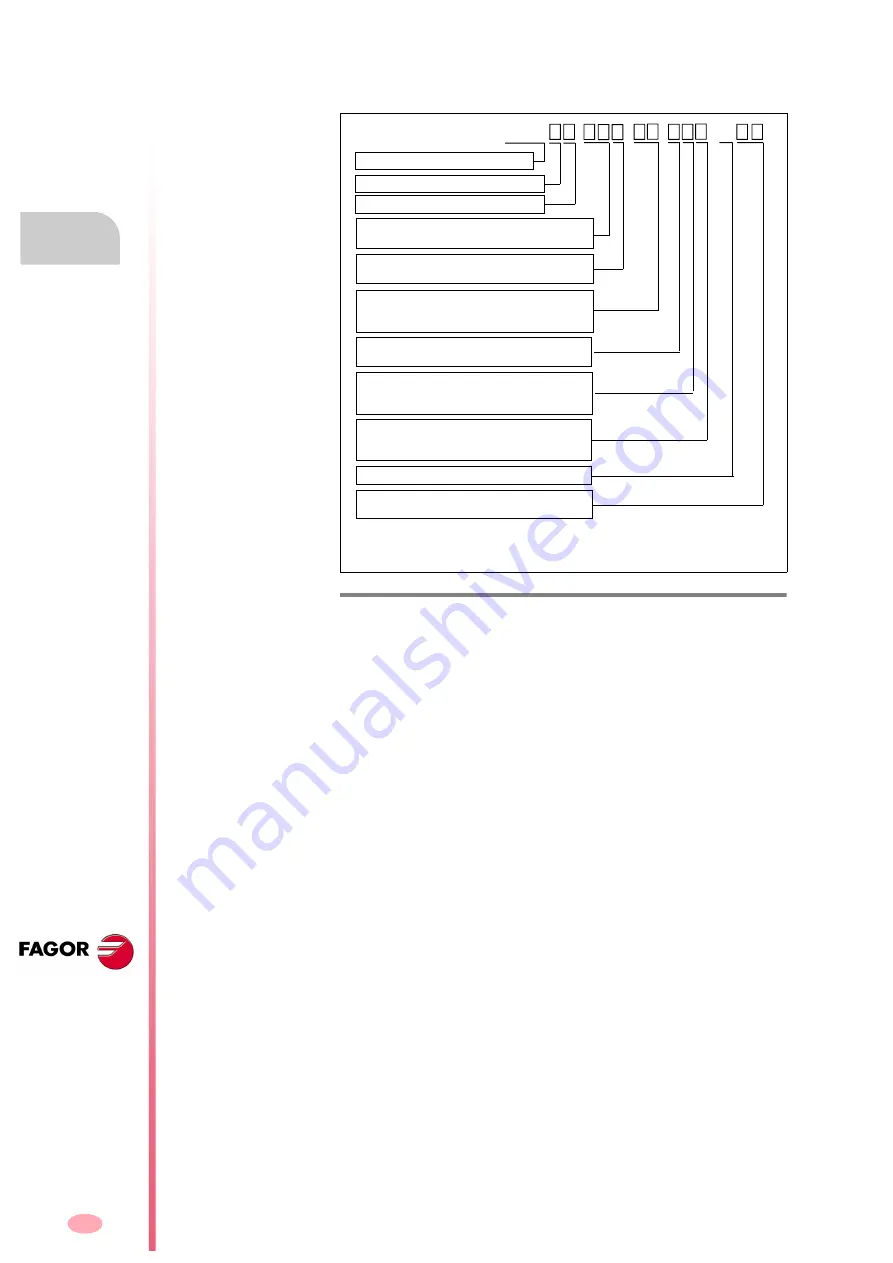

Sales reference of the synchronous servo motors, FXM.

F. H12/1

Sales reference of the synchronous servo motors, FXM.

0

Without fan

12 12

00 rev/min

30 30

00 rev/min

20 20

00 rev/min

40

40

00 rev/min

FXM . . . - X

MOTOR SERIES

SIZE 1, 3, 5, 7

LENGTH 1, 2, 3, 4, 5, 6, 7, 8

RATED

SPEED

WINDING

A

400 V AC

FEEDBACK

TYPE

FLANGE &

SHAFT

0

With standard keyway

BRAKE

OPTION

0

Without brake

SPECIAL CONFIGURATION X

F

220 V AC

1

With fan

1

With standard brake (24 V DC)

1

Without keyway

SPECIFICATION OF THE

SPECIAL CONFIGURATION 01 ZZ

E1

Sinusoidal SinCoder

A1

Absolute multi-turn SinCos

I0

Incremental TTL

E1

SinCoder Stegmann

TM

SNS 50 (with taper shaft), 1024 ppt

I0

Tamagawa

TM

Encoder OIH48 TS5214N510, 2500 ppt

A1

SinCos Stegmann

TM

SRM 50 (multi-turn), 1024 ppt

FAN

OPTION

(Neodine type H with double torque)

(only in sizes 5 and 7)

Summary of Contents for DDS

Page 1: ...DRIVE DDS Hardware manual Ref 1310...

Page 6: ...I 6 DDS HARDWARE Ref 1310...

Page 9: ......

Page 10: ......

Page 11: ......

Page 12: ......

Page 16: ...16 Ref 1310 DDS HARDWARE...

Page 30: ...1 DESCRIPTION 30 Description DDS HARDWARE Ref 1310...

Page 94: ...2 POWER SUPPLIES 94 Power supplies DDS HARDWARE Ref 1310...

Page 188: ...3 DRIVE MODULES 188 Drive modules DDS HARDWARE Ref 1310...

Page 204: ...4 AUXILIARY MODULES 204 Auxiliary modules DDS HARDWARE Ref 1310...

Page 232: ...SELECTING CRITERIA 5 232 Selection criteria DDS HARDWARE Ref 1310...

Page 266: ...7 CABLES 266 Cables DDS HARDWARE Ref 1310...

Page 312: ...8 INSTALLATION 312 Installation DDS HARDWARE Ref 1310...

Page 326: ...9 FUNCTIONAL SAFETY 326 Functional safety DDS HARDWARE Ref 1310...

Page 354: ...10 CONNECTION DIAGRAMS 354 Connection diagrams DDS HARDWARE Ref 1310...

Page 378: ...12 SALES REFERENCES 378 Sales references DDS HARDWARE Ref 1310...

Page 384: ...13 COMPATIBILITY 384 Compatibility DDS HARDWARE Ref 1310...

Page 385: ......