Operation Manual - Page: 13

NV-300T/301T Man: 9910 Soft: 2.xx

In absolute mode:

-

Press

until the ABS led comes on.

-

To preset part zero:

- Place the axis exactly over “0” and press:

C

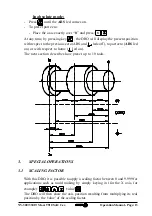

At any time, by pressing key

, the DRO will display the present position

with respect to the previous zero (ABS and

leds off), to part zero (ABS led

on) or with respect to home (

led on).

The next section describes how preset up to 10 tools.

3.

SPECIAL OPERATIONS

3.1

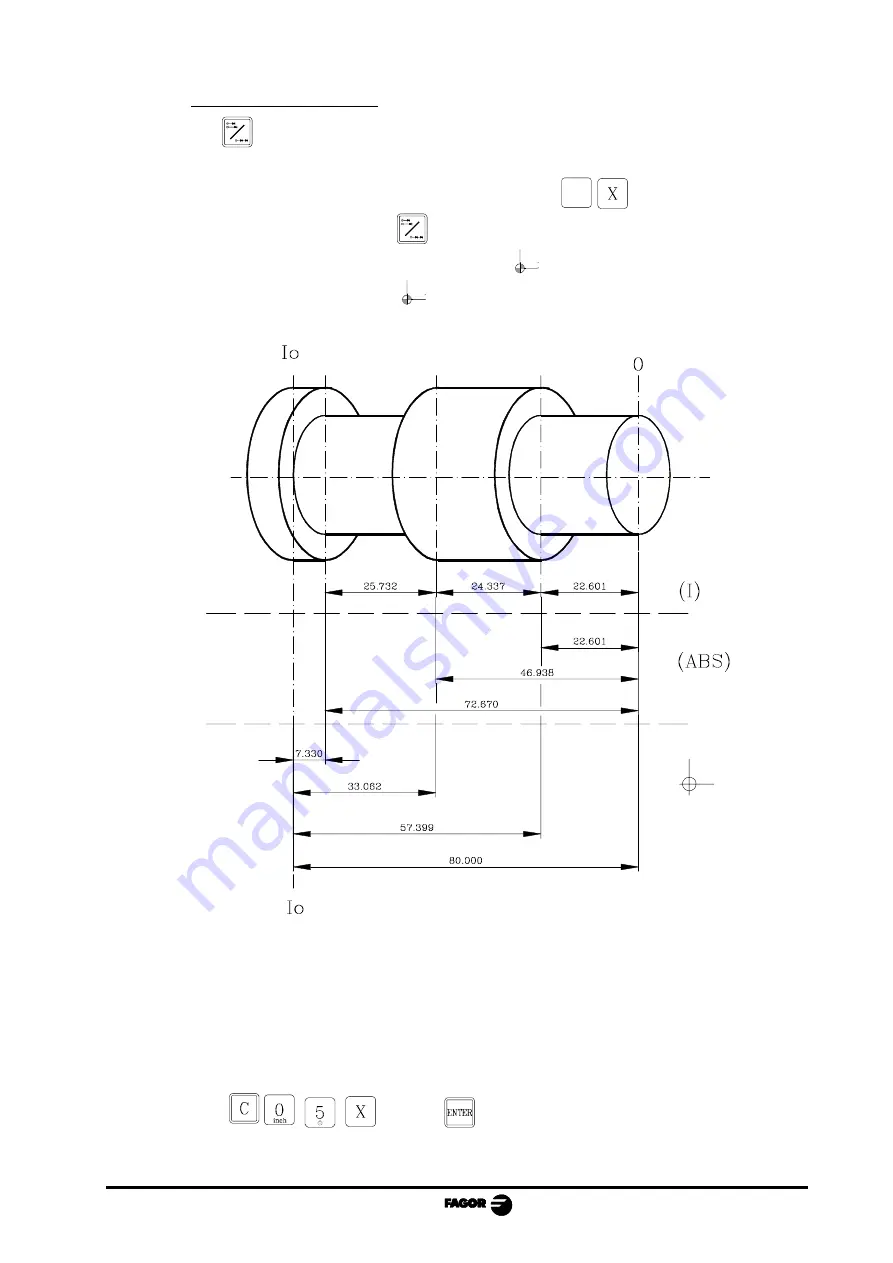

SCALING FACTOR

With this DRO, it is possible to apply a scaling factor between 0 and 9.999 for

applications such as mold making by simply keying in (for the X axis, for

example):

'value'

.

The DRO will then show the axis position resulting from multiplying its real

position by the 'value' of the scaling factor.