12

4.4 VENTILATION REQUIREMENTS

The following notes are for general guidance:

- It is not necessary to have a purpose provided air vent in the room or internal space in which the appliance

is installed.

- If the boiler is to be built into a small cupboard or compartment (i.e. at minimum clearances)and overheat-

ing can be forseen (i.e. close proximity to a cooking appliance etc) permanent air vents are recommended for

cooling purposes in the cupboard or compartment . The following table gives the minimum effective areas of

the vents.

Position of air vent

Air from room/int space.

Air direct from outside.

HIGH LEVEL

13000 mm²

13000 mm²

LOW LEVEL

7500 mm²

7500 mm²

4.5 ELECTRICITY SUPPLY

The appliance MUST be earthed. A mains supply of 230 V ~ 50 Hz single phase is required.

Wiring external to the boiler MUST be in accordance with current I.E.E. Wiring Regulations (BS 7671) and

any other relevant local regulations. The supply connection to the flying lead provided MUST be made to a

fused double pole switch having a 3 mm (1/8 in ) contact separation in both poles, serving only the boiler and

system controls, is a fused plug and socket or fused spur.

The external fuse rating should be 3A. This connection should be readily accessible and be made adjacent

to the boiler

4.6 GAS SUPPLY

- A Propane gas supply at 37m bar is required.

- Ensure the regulator is of sufficient capacity to carry the maximum boiler input plus the demand for any other

installed appliances.

- Ensure the connection between the supply/bottle and the caravan holiday home or park home is designed

so that no pressure drop occurs.

- No more that 3 m of 15mm pipe should be used. Where the supply exceeds 3 m the pipe should be suit-

ably sized only reducing to 15mm before the boiler

- A full bore isolation cock must be fitted in the supply close to the boiler.

- The complete installation must be tested for gas soundness.

4.7 WATER SYSTEMS - GENERAL

- This appliance is designed for connection to sealed central heating water systems.

- Prior to filling the central heating system (see section 6.2) It is recommended that where the system is

installed in a caravan holiday home, subject to non - continuous use, anti-freeze is used.

4.8 REQUIREMENTS FOR SEALED WATER

SYSTEMS

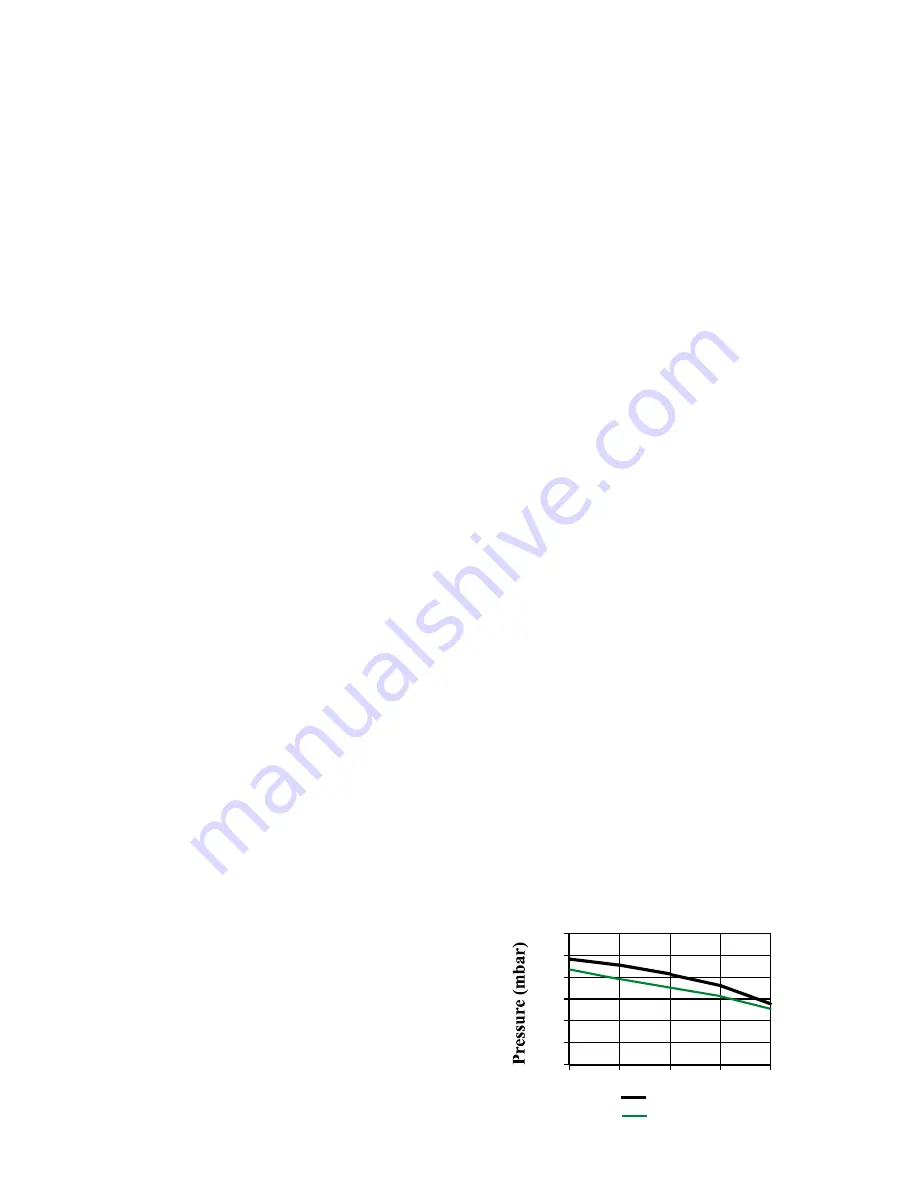

The heating system design should be based on the fol-

lowing information:

- The available pump head is given below.

- A minimum flow rate corresponding to a heating differ-

ential of 20

°

C must be obtained at all times.

0

100

200

300

400

500

600

0

200

400

600

800

Flow (l/h)

By-pass closed

By-pass open

AVAILABLE PUMP HEAD