20

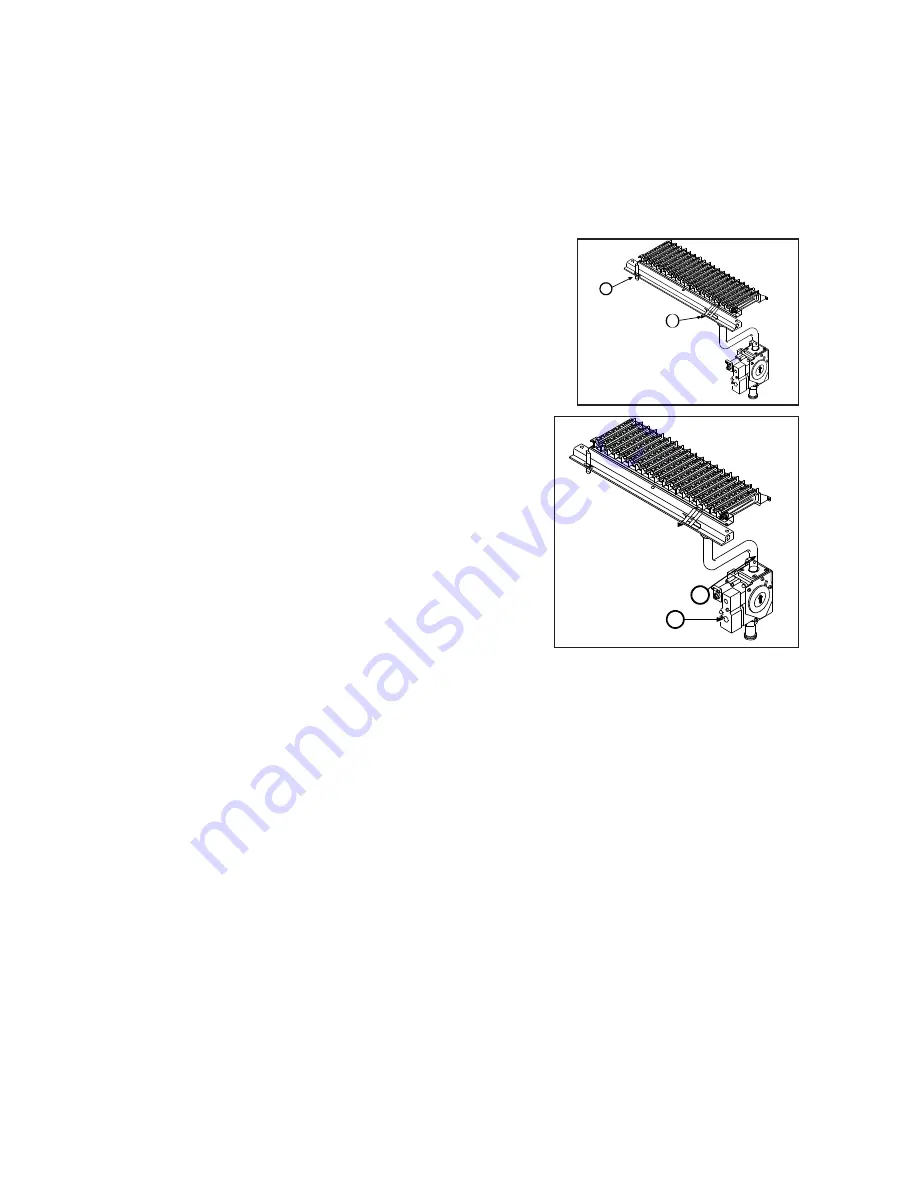

7.2 BURNER AND HEAT EXCHANGER INSPECTION AND CLEANING

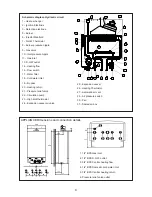

The front of the sealed air box must first be removed (6 screws) and care should be taken to avoid damag-

ing the seal. The combustion chamber cover can then be removed (4 screws) taking care not to damage the

delicate insulation material inside.

Inspect the burner and heat exchanger fins for debris and soot. Check also for rubbish below the burner.

7.3 IGNITION AND DETECTION ELECTRODES

With the combustion chamber cover removed check the condition of

the electrodes for any sign of wear or damage.

7.4 WATER CIRCUIT CHECKS

Inspect the pipe work inside the boiler for leaks. Check that the

pressure in the system is correct (1bar). Check the operation of the

relief valve by turning ¼ turn and check it closes without further

leakage.

Check the correct operation of the gauge. The pressure should

increase slightly as the temperature rises. Finally check the filter

which is situated in the cold water inlet pipe.

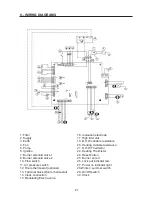

7.5 BURNER PRESSURE

This is factory set, but should you suspect a problem proceed as fol-

lows: There are two nipples on the gas valve, an inlet pressure nip-

ple situated at the lower end marked ‘in’ and a burner pressure

pressure nipple at the top marked ‘out’. The pressure at the inlet should be 37mbar for propane, less no more

than 2.5mbar pressure drop when the boiler is working in DHW mode.

The burner pressure nipple should give a reading of 14.6 mbar when the boiler is at full power on D.H.W.

mode. Remove the main cable plug to the gas valve to get a minimum burner pressure reading which should

be 2.9 mbar.

7.6 FINAL CHECKS

Turn all the controls to their max position so that the appliance begins to function. Check for gas leaks using

a suitable detector.

Check the boiler functions correctly in both central heating and domestic hot water modes. The orange indi-

cator should light up when the boiler is firing in either mode.

For more detailed servicing information, troubleshooting flow diagrams, self diagnostic codes, tech-

nical advice, spare parts etc, phone Morco on 01482 325456.

Our qualified corgi registered personnel are ready to help and advise you.

4

5

1

2