3

1.1.- GAS SAFETY (INSTALLATION AND USE) REGULATIONS 1996 (AS AMENDED)

It is the law that all gas appliances are installed by a registered person, in accordance with the above regu-

lations. Failure to install appliances correctly could lead to prosecution. It is in your own interest, and that of

safety, to ensure that the law is complied with.

WARNING: It is essential that the appliance is correctly earthed. An electricity supply of 230 V 50 Hz is

required, fused at 3 Amp.

Read these instructions carefully before attempting to operate the appliance. Comply with all applicable

warnings. Do not interfere with any sealed components, and use the appliance only in accordance with these

instructions.

1.2.- INTRODUCTION

The Fagor FEB-20E is a wall hung, room sealed, fan assisted, microprocessor controlled, fully modulating

gas combination boiler for providing both central heating and domestic hot water. The maximum heat output

in either heating or hot water mode is 23.7kW and priority is always given to the supply of hot water.

1.3.- PRELIMINARY WARNINGS

Check all of the gas pipe joints and make sure that gas reaches the boiler (with the gas cock turned on)

Make sure that the central heating circuit is completely full and vented. The pressure gauge should indicate

a pressure of between 0.75 and 1 bar with domestic cold water in the central heating circuit.

Make sure that the boiler is connected to the correct electricity voltage.

Make sure that the air intake and the combustion products outlet are not blocked.

1.4.- DOMESTIC HOT WATER SERVICE

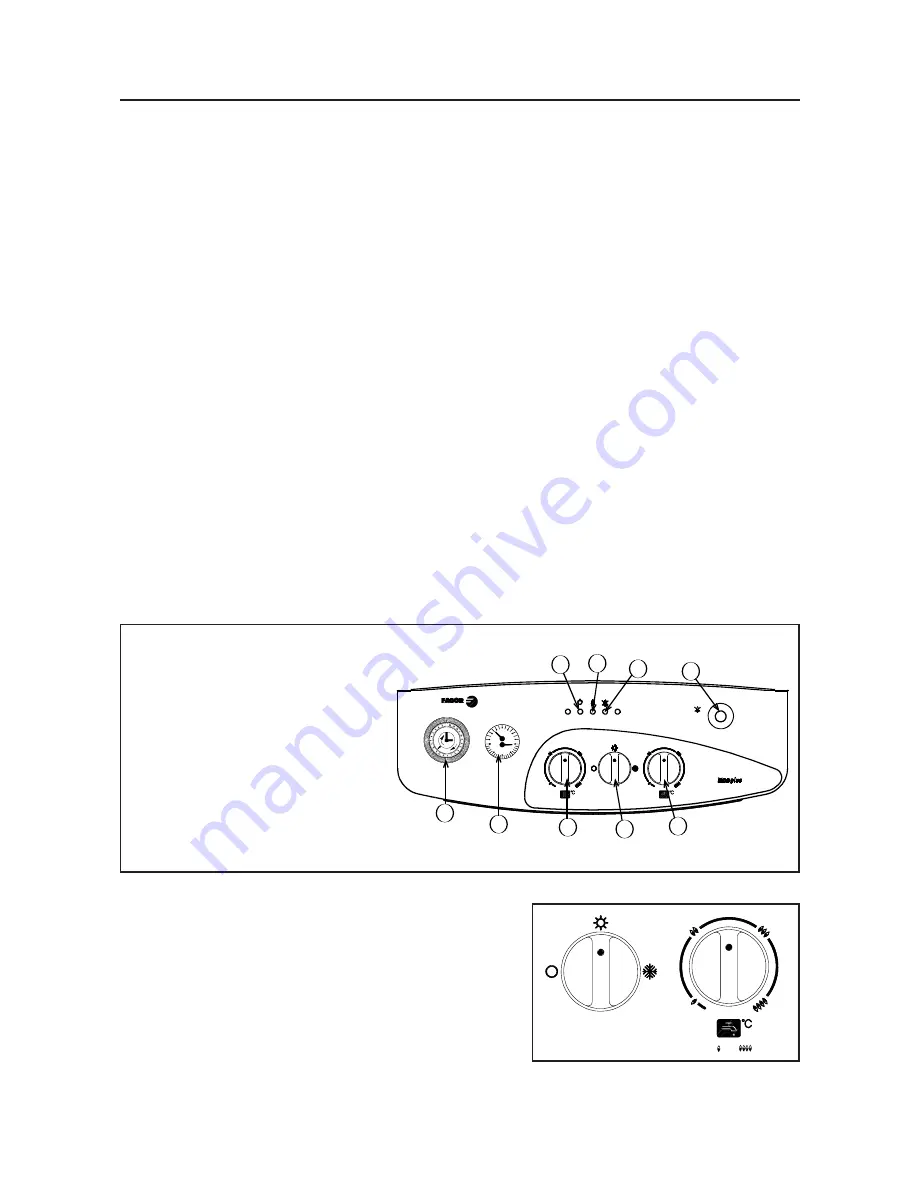

To turn on the boiler turn the main control switch to the summer

setting. The boiler is then ready to supply D.H.W. on demand.

Whenever you turn on any hot tap the boiler automatically turns

on by firing up the burner. By means of the D.H.W. temperature

selector knob, any water temperature of between 35 and 60

°

C

may be selected.

FEB-20E

4

0

3

2

1

bar

0

60

120

100

20

80

40

6

9

6

12

3

1

8

9

5

4

3

2

1

7

Position: min. max

1.- USERS INSTRUCTIONS

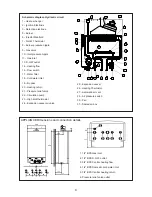

CONTROL PANEL.

1.- Programmable timer

2.- Heating temperature and pressure

gauge

3.- Central heating temperature selector

4.- Main control switch

5.- D.H.W. temperature selector

6.- Green neon light (boiler ready)

7.- Orange neon light (burner functioning)

8.- Red neon light (boiler locked out)