QCIG-8/16

Q

uer

C

us SERCOS-II Drive System.

I

nstallation

G

uide. Ref.1801/B

Install the QUERCUS system as far away as

possible from air inputs and outputs.

Carry out periodic maintenance on air filters.

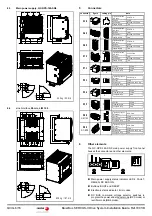

Mechanical considerations

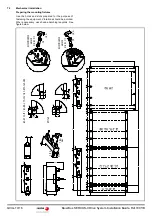

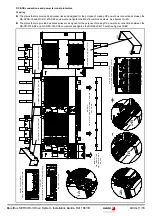

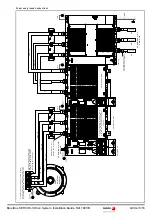

Electrical considerations

Electrical conditions

Power voltage input:

3 AC, 400 V AC (1-10 %) to 480 V AC (1+10 %)

DC BUS: 500/800 V DC

Electrical precautions

Once the installation has been completed and before

handling any of the terminals on the QUERCUS

equipment, follow the instructions in the order below:

Indications regarding EMC

Electromagnetic Compatibility is covered by the following

standards:

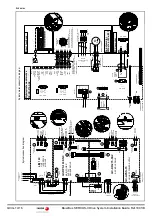

Conditions

Standard

Test reference

Transport

Vibration

Acc. to:

IEC 60721-3-2

Class 2M1, vibration sinusoidal

2 Hz < f

9 Hz, 3.5 mm amplitude

9 Hz < f

200 Hz, 1 g

200 Hz < f

500 Hz, 1.5 g

Shock limits

Acc. to:

IEC 60721-3-2

IEC 61800-2

Class 2M1,

equipment in its

transport package

Operation

Environmental

testing-vibration

(sinusoidal)

Acc. to:

IEC 60068-2-6

Test Fc

Vibration sinusoidal

10 Hz

f

57 Hz,

0.075 mm

constant amplitude

57 Hz

f

150 Hz,

1 g constant acceleration

Degrees of

protection

provided by

enclosure

(IP code)

Acc. to:

EN 60529

IP xx.

It should be installed

inside of an electrical

cabinet

Acc. to:

IEC 61800-5-1

Protection

class

Class I (with protective conductor system)

Mains overvoltages, category III

Pollution degree 2

Altitude < 2 000 m (6561.66 ft) asl

Distribution systema: TN/TT.

Diagrams with grounding on a vertex are not

permitted.

MANDATORY.

Only qualified personnel who know and understand the

contents of this manual and all the other documentation

related to this product and have been properly trained on

this safety subject to recognize and prevent existing

risks, are authorized to work with this QUERCUS system.

Only qualified personnel may install, set up, repair and

maintain this equipment.

MANDATORY.

The installation must be fully compliant with all the

requirements of the local and national electrical

regulations and all other applicable regulations.

MANDATORY.

As for possible high leak currents (3.5 mA AC or 10 mA

DC), use a protection ground wire with a cross section of

at least S/2, where S (mm²) is the cross section of the

conductor wires connected to the power supply terminals.

Comply with local regulations on grounding.

WARNING.

The system must always be installed before applying

voltage according to the EN 60204-1 standard. Ignoring it

may cause serious injuries, even death.

WARNING.

Always disconnect all power supplies, including the

external power that feeds the control board that could

be present.

Wait at least 10 minutes · MAX DISCHARGE TIME:

10 min · until the capacitors of the DC bus are fully

discharged. This precaution is indicated on the cover

of the DC bus.

There is no assurance that there is no voltage in the

DC bus when the D7 indicator light is turned off.

Accordingly, never handle the DC bus even when the

D7 led is turned off.

Make sure that the DC BUS voltage is lower than 60

V DC. This precaution is indicated on the front of the

equipment near the cover of the DC bus with the

legend · DANGER, RISK OF ELECTRIC SHOCK ·.

Assemble and close all covers and connect the

QUERCUS system to the ground before supplying

voltage.

Eliminate the mains voltage using an appropriate

switch to obtain a condition without voltage.

MANDATORY.

T h e g r o u n d i n g c a b l e s h o u l d c o m p l y w i t h t h e

corresponding (applicable) standards. Always connect

the ground to the cable shields at both ends, knowing that

the shields are not protection ground conductors.

MANDATORY.

The electrical installation my comply with standard EN

60204-1.

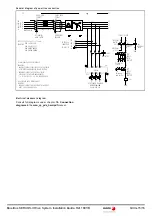

EN 61800-3:2004

/A1:2011

* note)

Category C3. Adjustable speed electrical

p o w e r d r i v e s y s t e m s . P a r t 3 : E M C

requirements and specific test methods.

IEC 61800-5-2: 2016 Adjusta ble sp eed elec trical power d rive

systems - Part 5-2: Safety requirements -

Functional.

* note)

MANDATORY.

The EMC directive defines equipment as any device or

fixed installation. This device is identified as a fixed

installation and is meant to work inside an electrical

cabinet according to category C3 and meeting the EN

61800-3 standard.

* note)

MANDATORY.

The installation that includes this product may need a

harmonic suppressing filter to comply with the EN 61800-

3 standard which is harmonized with the EMC Directive.

Otherwise, when applying solutions to limit the harmonics

in each QUERCUS system included in the installation

could be an expensive solution and/or would not make any

technical sense. It is better to apply a global solution.