Q

uer

C

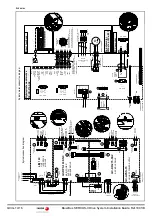

us SERCOS-II Drive System.

I

nstallation

G

uide. Ref.1801/B

QCIG-9/16

EMC instructions for equipment installation

Use equipotential wires in systems with:

Repair

* note)

MANDATORY.

This type of PDS is not intended to be used on a low-

voltage public network which supplies domestic

premises. Radio frequency interference is expected if

used on such a network. However, equipment whose

compliance with the essential requirements set out in

item

1. General requirements

of annex I of the EMC

Directive that are not ensured in residential areas will

include an indication with this use restriction.

MANDATORY.

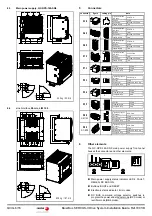

Use the copper plates that are provided as

accessories in the assembly.

Make the connections with wide contact surfaces for

the metal parts.

Remove the paint from contact surfaces.

Try to increase conductivity on two-dimensional

contacts.

Install a protection circuit if there is a risk of

overvoltage.

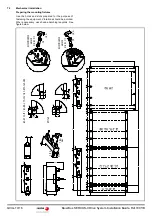

Route the electrical energy supply lines from the lines

carrying the information.

Note. The electrical field which could induce voltage

spikes on the information lines decreases with

distance.

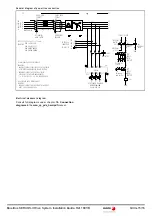

Route the motor cable at a distance of at least 20 cm

from the signal cable or use shielding plates between

the motor cable and signal cable.

Do not run field bus cables and signal through a single

conduit with DC and AC lines with voltages over 60 V.

The field bus cables, signal lines and analog lines can

be installed in a same conduit.

Recommendation. Separate the conduits where the

cables are running at least 20 cm and make them as

short as possible. Do not install unnecessary cable

loops and use short cables from the central ground

point for connecting to a ground point outside the

electrical cabinet.

Avoid induction loops by choosing common routes for

power, signal and data circuit cables.

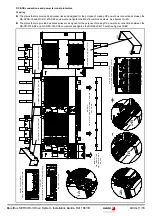

Use shielded cables for power supply and motor.

On shielded cables, the unshielded portion of the

cable used to connect them to the connectors must be

as short as possible in order to reduce radiated

emissions.

Use simple shielding for the motor encoder cable. The

system complies with current regulations regarding

immunity with simple shield.

MANDATORY.

Installations of large areas.

Different voltage sources.

Mains through several buildings reducing the current

in the cable shield and the emissions. Connect to

ground the electrical cabinet, the door, the mounting

plate, with ground straps or cables with a cross section

larger than 10 mm² (AWG 6).

MANDATORY.

The ground shields of the digital signal wires must be

connected at both ends to a large surface or through

a conductive housing of the connector. This reduces

disturbances that affect the signal cables and also the

emissions.

The ground shields of the analog signal wires must be

connected directly to the device (signal input),

reducing the ground loops due to low frequency

disturbances.

When a unit does not have a ground connection, the

shield must be connected on the side of the unit

connected to ground.

To connect large cable shield surfaces, use cable and

ground clamps.

Run a single shielded cable, in one piece, without

joints. If a cable must necessary be cut for the

installation, connect it with the shield connections and

through a metal cover at the cut (joint) point. In the

worst case, if it is not possible to use shielded

connectors, keep a minimum length of cable exposed

to disturbances guaranteeing a good connection

between the shields.

Mount switching devices such as contactors, relays

or electro-valves with interference suppression

elements or arc suppressors (e.g. diodes, varistors,

RC circuits).

Install power and control components separately.

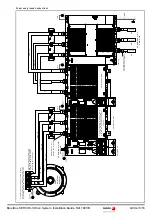

Use equipotential cables when having long lines to

reduce the current through the cable shield.

When connecting power cables, the shield of this

cable should be connected to a ground bar.

DANGER.

Neither the user nor the machine manufacturer is

authorized to modificate or repair the drive, not even

to replace boards.

In the event that any safety function suffers a failure,

replace the drive with the same model of the same

version or later and set identical parameters on the

replacement model.

Conduct the partial acceptance test.