www.Fagorcommercial.com

PAGE 9

REACH-INS OPERATIONAL SERVICE MANUAL / Rev.JUN. 2015

3.5

LEVELING

Set unit in its final location. A level cabinet looks better and will perform better. Effective condensate

removal and door operation will be effected by leveling. Machine must be leveled front to back and

side to side with a level tool. Castors k i t w i l l include shims for leveling. Insert the shim between the

castor and the frame rail. (See installation of castors). Lock front castors so cabinet does not move.

Ensure drain hose is inside drain pan.

3.6

ELECTRICAL CONNECTIONS

Refer to the amperage data in this manual, or on data plate, and your local code or the National

Electrical Code to be sure unit is connected to the proper power source. Verify correct incoming

voltage according to the Data Plate information.

Do not, under any circumstances, cut or remove the ground prong from the power cord. Fagor units

must be properly grounded.

NEVER USE AN EXTENSION CORD! Fagor will not warranty any unit that has been

connected to an extension cord.

Fagor equipment must be grounded and connected in accordance with NEC Article 422Appliances.

DANGER:

Power must be turned off and disconnected from the power source whenever performing

maintenance, repair or cleaning the condensing unit.

If machine is still running when power is off, disconnect power at the circuit breaker before

unplugging the machine.

WARNING:

Machine and compressor warranties are void if failure is due to improper electrical

Summary of Contents for QR-1

Page 1: ...REFRIGERATORS AND FREEZERS Manual for installation use and maintenance...

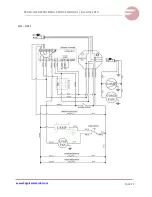

Page 11: ...www Fagorcommercial com PAGE 11 REACH INS OPERATIONAL SERVICE MANUAL Rev JUN 2015...

Page 22: ...www Fagorcommercial com PAGE 22 REACH INS OPERATIONAL SERVICE MANUAL Rev JUN 2015 QF1 QVF 1...

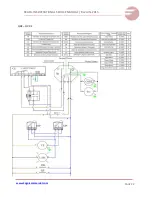

Page 23: ...www Fagorcommercial com PAGE 23 REACH INS OPERATIONAL SERVICE MANUAL Rev JUN 2015 QR2 QVR 2...

Page 24: ...www Fagorcommercial com PAGE 24 REACH INS OPERATIONAL SERVICE MANUAL Rev JUN 2015 QR 1G QVR 1G...