- 9 -

GB

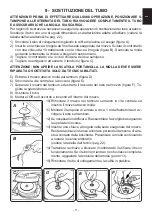

9 - REPLACEMENT OF THE HOSE

WARNING: BEFORE PERFORMING ANY OPERATION, POSITION THE STOPPER AT

THE END OF THE HOSE, REEL THE HOSE COMPLETELY AND MAKE SURE THAT THE

SPRING IS COMPLETELY SLACKENED.

For safety reasons, operations of hose replacement must be carried out at the bench.

Use a hose with dimension and pressure characteristics suited to the use (see table of cha

-

racteristics page 22).

1) Take the inlet hose off by removing the plastic cap and the seeger (figure A).

2) Insert a 5 mm hexagonal wrench into the axle of the spring linkage shaft. Unfasten the

nut with a 19 mm wrench, holding in place with the hexagonal wrench (figure B). Release

the spring by turning the hexagonal wrench slowly clockwise.

3) Remove the nut and the 4 attachment screws from the two half-casings.

4) Remove the half-casing and take out the drum (figure C).

WARNING: DO NOT OPEN THE SPRING CASING. SPRING REPAIR OR REPLACEMENT

OPERATIONS MUST ONLY BE PERFORMED BY QUALIFIED TECHNICIANS.

5) Take the spring hub out of the drum (figure D).

6) Unfasten the central screw and remove the bushing (figure E).

7) Separate the hub from the drum and take the hose coupling out of the hub (figure F).

Remove the o-ring.

8) Replace the hose.

9) Position the o-ring on the coupling and insert the coupling into the hub hole.

A

B

C

D

E

F

10) Reposition the hub in the drum by fastening the central screw

and insert the spring hub.

11) Fit the stop approximately 1 m from the opposite end of the

hose and reel the new hose on the drum.

12) Grease if required. Reassemble the reel, following the opera-

tions in reverse order.

13) Insert the hex wrench into the axle after the side bodies have

been attached. Turn the wrench anti-clockwise and bring the

hose rubber stop into contact with the roller support. Pre-load

the spring while continuing to turn anti-clockwise the wrench

(see table of technical data page 22).

14) Hold the wrench in position and fasten the nut. Perform a fun-

ctional check. If the hose does not go in completely or does not

come out completely, readjust the tension of the spring

(point 13).

15) Reposition the inlet hose and the plastic cap.