Safety pressure valve

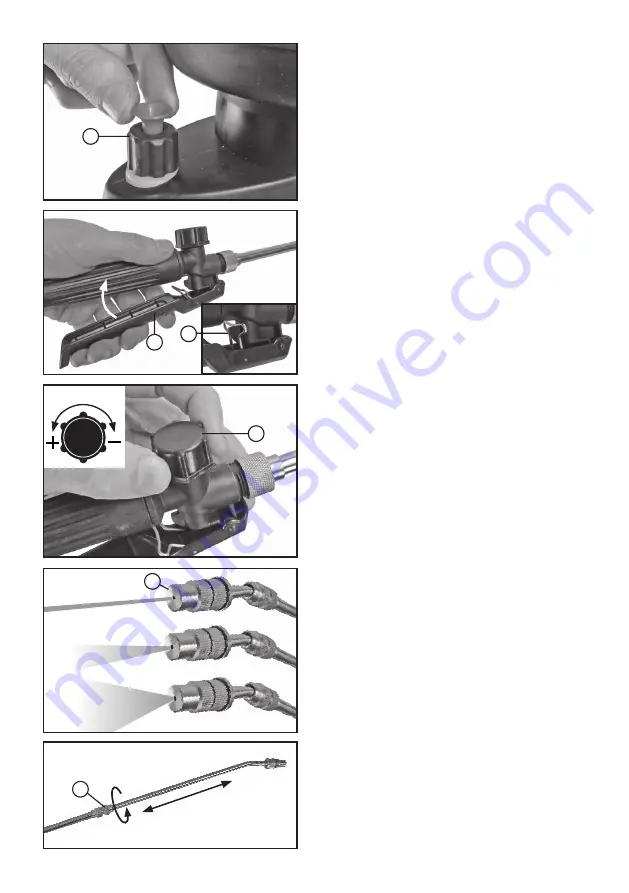

(Fig.15)

The safety pressure valve (2) will open when

the pressure exceeds 2.5bar. It can also be

opened manually to vent remaining pressure

prior to opening.

To open the valve manually, pull up on the

valve to release pressure.

Spray operation

(Fig.16)

The sprayer is operated by depressing the

trigger (9).

For continuous spraying, pull the metal locking

catch (9.1) forward and locate onto the plastic

lug, locking the trigger in the open position.

Flow rate

(Fig.17)

The force of the spray can be regulated using

the flow adjustment dial (9.2) located on the

trigger assembly.

Turn the dial anti-clockise for increased flow

rate and clockwise to decrease the flow rate.

Variable spray pattern

(Fig.18)

The spray pattern can be varied from a fine jet

through to a wide fan by rotating the nozzle (6).

Note:

Do not undo the nozzle too far as this

will cause liquid to leak from the rear.

Note:

If the nozzle continues to drip after

the trigger handle has been shut off, there is

probably air in the discharge system (nozzle,

handle, tap and hose). Purge the system by

turning the nozzle to jet and operating the

trigger on and off in short bursts, until the

liquid shuts off cleanly. Collect any liquid in a

separate container to use later.

Telescopic lance

(Fig.19)

Unscrew nut (5.1), pull lance out to desired

length from 520 to 1150mm and retighten nut.

2

Fig.15

6

9

9.1

9.2

Fig.18

Fig.16

Fig.17

Fig.19

7.1