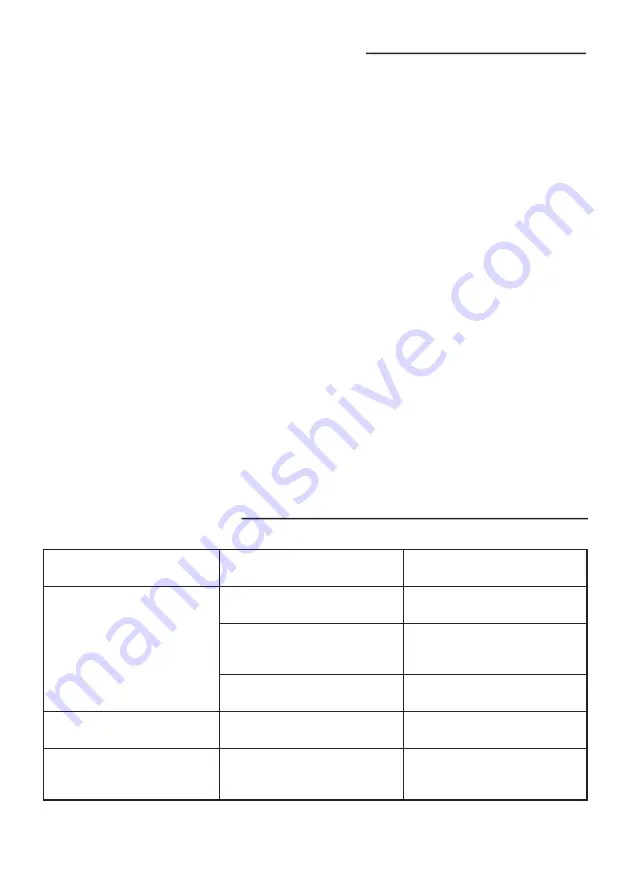

Troubleshooting

Fault

Problem

Solution

Weak or no spray.

Non-pressuration.

Check and tighten

connections, if necessary.

Loss of pressure

Check gaskets are lubricated

and show no signs of wear -

replace if necessary.

Obstruction.

Check for possible blockage in

nozzle, trigger or outlet hose.

Distorted spray.

Obstruction.

Check for possible debris

partially obstructing nozzle.

Leakage.

Possible sediment

accumulation on sealing

surfaces.

Check sealing rings are free

from debris and sedimant -

clean or replace if necessary.

Looking After Your Sprayer

Blocked Nozzles

If a nozzle becomes blocked or fails to spray the correct pattern, unscrew the nozzle

tip and clean the components under running water or a water jet. Do not use a metallic

instrument to unblock a nozzle as this may alter the nozzle aperture making the nozzle

ineffective.

Cleaning

Add a little detergent and some warm water (not hot) to the sprayer and spray through the

system. Repeat the above operation with clean cold water. Finally check that the nozzle

is free from any residue. Your sprayer will now be perfectly clean and ready for its next

use. Always dispose of any unused garden chemicals safely and in accordance with the

manufactures instructions.

After Use

Always release the pressure from the tank before storage. Hold or lock the sprayers trigger

in the on position until the pressure in the tank has been released or pull up on the safety

valve to release the pressure.

Storage

Store the sprayer under cover and avoid freezing temperatures. For winter storage ensure

that all fluid is removed from the tank, hose and lance before storing. Do not store in direct

sunlight, in a greenhouse or any areas where extremes of heat may occur.