13

REPAIRS AND MAINTENANCE

13.1

Maintenance

Correct maintenance ensures longer working life of the machine, better running conditions, good sewing

results, and is a guarantee for the safety measures provided by the manufacturer.

13.2

Regular maintenance operations.

The intervention regularity is reported to the 8 daily working hours and to the maximum speed.

Operation

Machine part

Regularity

Lubrification

Inside the shuttle before inserting the

Each bobbin change

bobbin

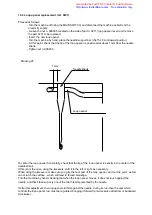

Whirl, with a few drops of oil through

Several times a day

the hole in the plate

Connection inside the horn

Each week

All holes in the horn

Each day

All holes marked with red paint.

Each week

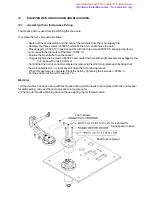

Greasing

Cams, rollers, pins and runner guides

Each week

Visual control check

Compressed air tubing and connections

Each week

Check control and adjustment of cogged pinion

for whirl control (see par. 6.4.4)

Each week

Check control of the antirotation-block play

n. 5474.00 (see inside the par. 10.8) Each month

Filter inspection

Compressed air entry filter

Each month

Filter on the compressed air supply line

Each month

to the machine

Condensation purge

Condensation discharge on the compressed

Each week

air supply line to the machine

Condensation discharge on the machine

Each week.

Safety devices In order to check the right functionioning of the safety devices, verify that, having the

on the machine machine connected and restarted, at every opening of the case (which protect the frontal,

superior and inferior parts of the machine) becomes operating the emergency stop

device, whose pilot lamp will light automatically. If not so let check by qualified stuff the

functionality of the microswitches and of the emergency stop device.

Daily

Generated by Foxit PDF Creator © Foxit Software

http://www.foxitsoftware.com For evaluation only.