2.

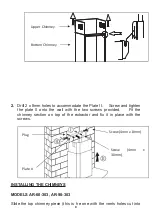

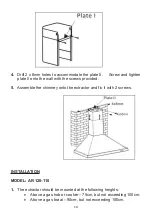

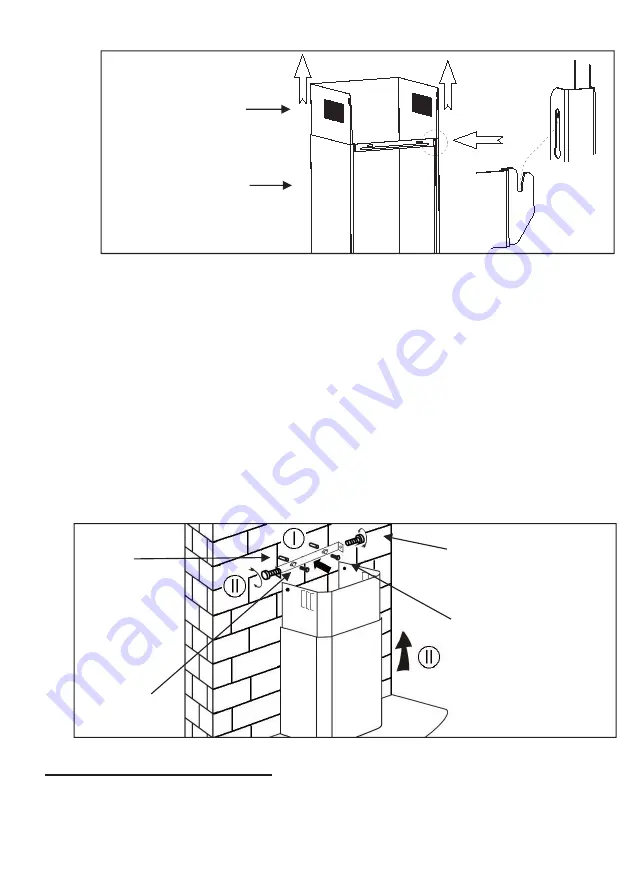

Drill 2 x 8mm holes to accommodate the Plate II.

Screw and tighten

the plate II onto the wall with the two screws provided.

Fit the

chimney section on top of the extractor and fix it in place with the

screws.

INSTALLING THE CHIMNEYS

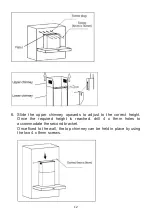

MODELS AR-60-303, AR-90-303

Slide the top chimney piece (this is he one with the vents holes cut into

hƉƉĞƌ ŚŝŵŶĞLJ

ŽƚƚŽŵ ŚŝŵŶĞLJ

WůƵŐ

WůĂƚĞ //

^ĐƌĞǁ ;ϰŵŵ dž ϴŵŵͿ

^ĐƌĞǁ

;ϰŵŵ

dž

ϯϬŵŵͿ

8