41

Attention points during operation

-

Make sure nobody enters the safety zone during the lifting or lowering of the vehicle.

-

When the vehicle is lifted to the desired height, the lift must be locked. Only when the

lift is locked, mechanics are allowed to work on the car.

-

Before lowering the vehicle, the work areaunder the car must be cleaned.

-

Check all moving parts weekly, grease the lifting bodies and check if all moving parts are

well lubricated and in the correct position.

-

Lower the lift completely and check the oil level in the tank. Make sure the oil tank is

filled almost to the MAX mark.

-

When you are not able to solve a problem, contact your Falco retailer.

6.

Safety features

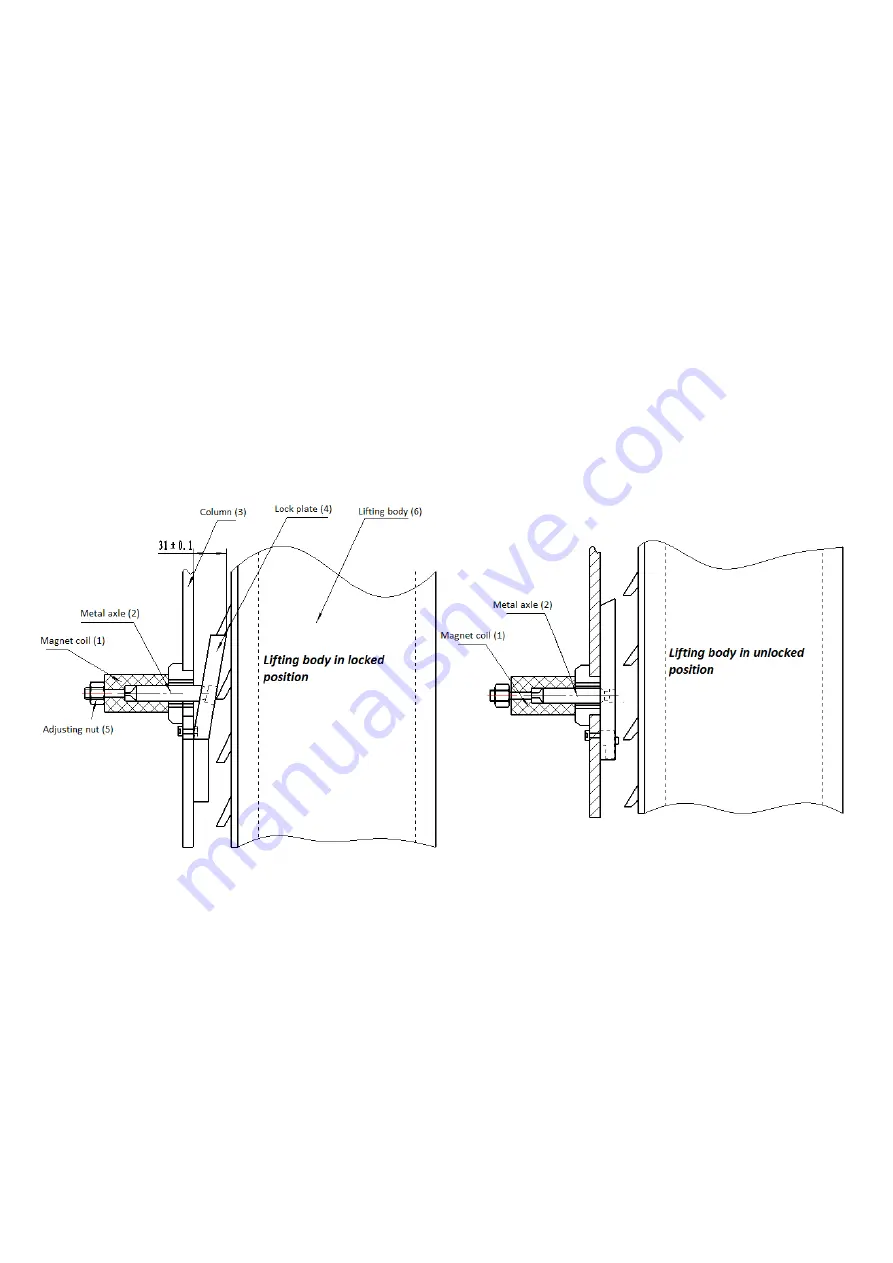

Automatic safety locks

Every column is provided with two safety locks, consisting of a Magnet coil (1), Metal axle (2),

Column (3), Lock plate (4), Adjusting nut (5) and Lifting body (6) (refer to figure 21).

How the safety lock-mechanism works

During lifting and locking there is no power on the Magnet coil (1), the Lock plate (4)leans forward

into the Column (3). In this position the Lock plate (4) will fall into the recess between the angled

mounting plates of the Lifting body(6) and block the Lifting body. During lifting the angled mounting

plates move flawlessly across the Lock plates (4), this produces a clicking sound.

During lowering the Magnet coil (1) is powered, this retracts the Metal axle (2) and Lock plate (4)

(fig.22). The angled mounting plates of the Lifting body (6) can now move past the Lock plate (4)

without being blocked. The lift can now be lowered to the desired height.

Fig.21

Fig.22