31

WARNING SERVICING TO BE CARRIED OUT ONLY BY AN AUTHORISED PERSON

Disconnect from electricity before servicing. Check appliance is safe when you have finished.

Servicing Notes

This appliance must be serviced by a Authorised Person in

accordance with the instructions.

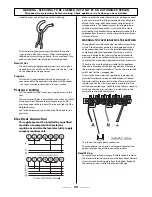

When servicing or replacing gas carrying components

disconnect from gas before commencing operation and

check appliance is gas sound after completion. When

checking for gas leaks use a liquid leak detector at all joints

and connections to check for leaks in the system. Use a

product specifi cally manufactured for leak detection.

Leak testing of the appliance shall be conducted in

accordance to the manufacturer’s instructions.

CAUTION: DO NOT USE A FLAME TO CHECK FOR

GAS LEAKS.

Do not use re-conditioned or unauthorised gas controls.

Disconnect from electricity supply before commencing

servicing, particularly before removing any of the following:

control panel, side panels, cooktop tray, or any of the

electrical components or cover boxes. Before electrical

reconnection check that the appliance is electrically safe.

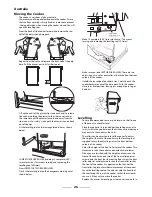

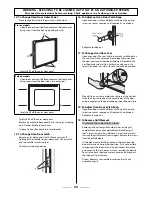

1 To Remove the Control Panel

Disconnect from electricity supply.

Classic model only

Remove the handrail by removing the 2 end bracket

fi xing screws.

Pull off the push fi t control panel end caps at each end

and remove the end fi xing screws under the end cap.

Open the oven door & or grill door and remove the fi xing

screws underneath the control panel. NB some models have

a plate under the control panel held in place by the bottom

fi xing screws.

Pull off all the control knobs.

Other models

Slide the control panel to the right.

Pull the control panel forward. Take care not to damage or

strain the wiring.

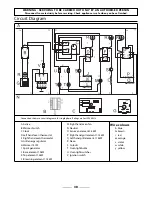

Disconnect the wiring from the rear. Reassemble in reverse

order. When replacing leads refer to the wiring diagram.

Check operation of timer.

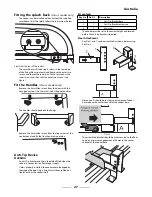

2. To

Remove

Hotplate

Trays

Disconnect from electricity supply.

Pull the cooker forward to gain access to the rear

Left hand tray

From the rear remove the screws securing the fl ue

grille to the hotplate tray. Remove pan supports,

burner heads and caps. Remove the 4 screws and

washers holding the hotplate tray to the frame.

Raise the front of the hotplate then withdraw.

Right hand tray

From the rear remove the screws securing the fl ue

grille to the hotplate tray. If the LH hotplate has

not been removed, slacken the screws holding

the L H tray. Remove pan support, burner head,

caps and trim rings. Remove the screws holding

the Wok burner to the hotplate. Remove the

two screws and washers holding the RH tray to

the frame. Press the Wok burner down slightly

and, taking care not to damage the Wok burner

electrode, slide the tray about 30mm to right to

clear the locating brackets on the R H side. Lift tray

slightly at the front and taking care not to stress

the Warmer/lead junction, disconnect the leads

to the Warmer neon and separate the leads at the

piggybacks. Withdraw the hotplate.

Reassemble in reverse order ensuring that the leads are

reconnected. When replacing the RH hotplate take care not

to damage the ignition electrode of the Wok burner.

It is important that the rear fi xing screws are refi tted as they

from part of the cooker earthing.

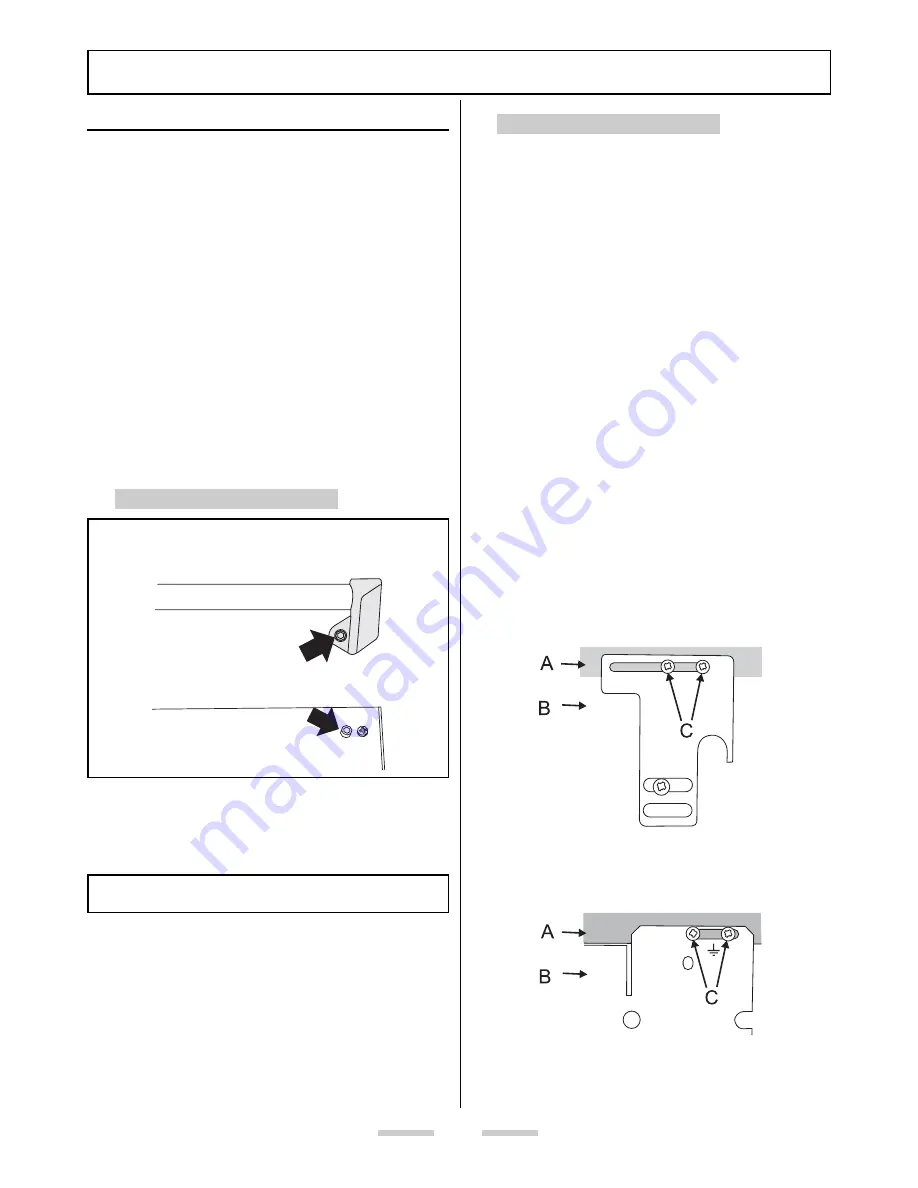

On some models there is a separate plate.

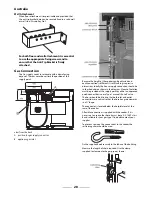

A fl ue grill, B cooker backsheet, C earthing/fi xing screws

On others it is a tag on the cooker backsheet.

It is important that the tag is on the outside and that both

fi xing screws are fi tted.

A fl ue grill, B cooker backsheet, C earthing/fi xing screws

Check for correct burner operation.