THE DUNMORE WOOD BURNER NON BOILER STOVE

INSTALLATION INSTRUCTIONS

GENERAL

When installing and maintaining your Stove respect

basic standards of fire safety. Read these instruc-

tions carefully before commencing the installation.

All relevant European and National Standards must

be complied with when installing this appliance.

Failure to do so may result in damage to persons

and property. Consult your local Municipal office

and your insurance representative to determine

what regulations are in force. Save these instruc-

tions for future reference.

Special care must be taken when installing the stove

such that Health & Safety requirements are met.

Handling

Adequate facilities must be available for loading,

unloading and site handling.

Fire Cement

Some types of fire cement are caustic and should

not be allowed to come into contact with the skin. In

case of contact with the skin wash immediately with

plenty of water.

Asbestos

This stove contains no asbestos. If there is a possi-

bility of disturbing any asbestos in the course of

installation then please seek specialist guidance and

use appropriate protective equipment.

Metal Parts

When installing or servicing this stove care should

be taken to avoid the possibility of personal injury.

“IMPORTANT WARNING”

This stove must not be installed into a chimney that

serves any other heating appliance.

2

The complete installation must be done in

accordance with current Standards and Local

Codes. It should be noted that the requirements

and these publications may be superseded during

the life of this manual.

FLUES

Flues should be vertical wherever possible and

where a bend is necessary, it should not make an

angle of more than 45

o

with the vertical. Horizontal

flue runs should be avoided except in the case of a

back outlet from the appliance, when the length of

the horizontal section should not exceed 150mm.

In order to minimise flue resistance and to make

sweeping easier it is recommended to use 2 x 45

o

bends rather than a 90

o

bend.

The flue termination point must be located to min-

imise any wind effects. Wind effects of suction,

pressure zones and turbulence can be created by

the roof and adjacent objects. Wind effects can also

be created by natural land contours.

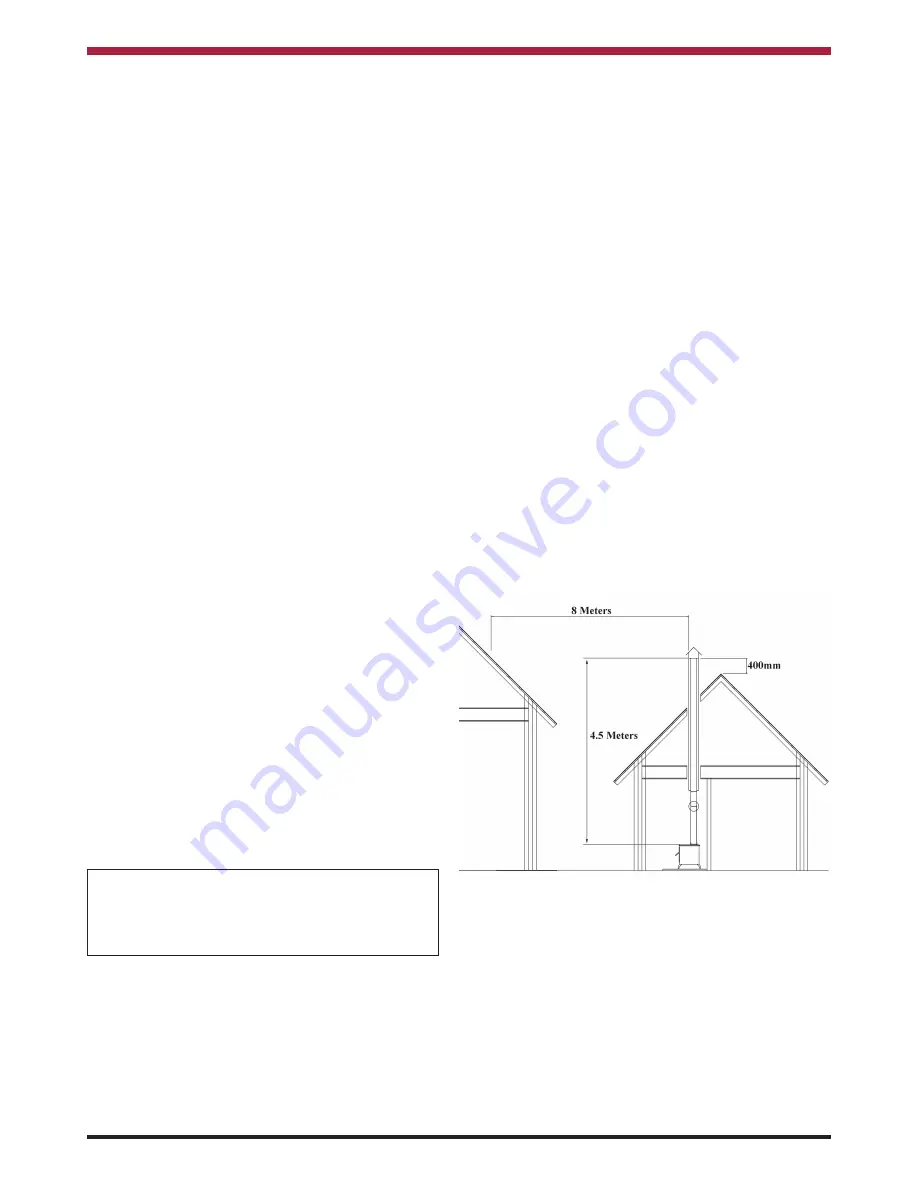

To minimise the wind effects, the flue termination

point should be located a minimum of 400mm mea-

sured vertically from the roof or any other object that

may cause an obstruction and 8 meters measured

horizontally. Where this termination point does not

suffice it may be necessary to extend the flue pipe.

(See Fig.1)

Fig.1