If it is found that there is excessive draught in the

chimney then a draught stabiliser should be fitted.

Fitting of a draught stabiliser will affect the require-

ment for the permanent air supply into the room.

Adequate provision e.g. easily accessible soot door

or doors must be provided for sweeping the chimney

and connecting fluepipe.

ALL FLUE INSTALLATIONS ARE THE

RESPONSIBILITY OF THE CUSTOMER.

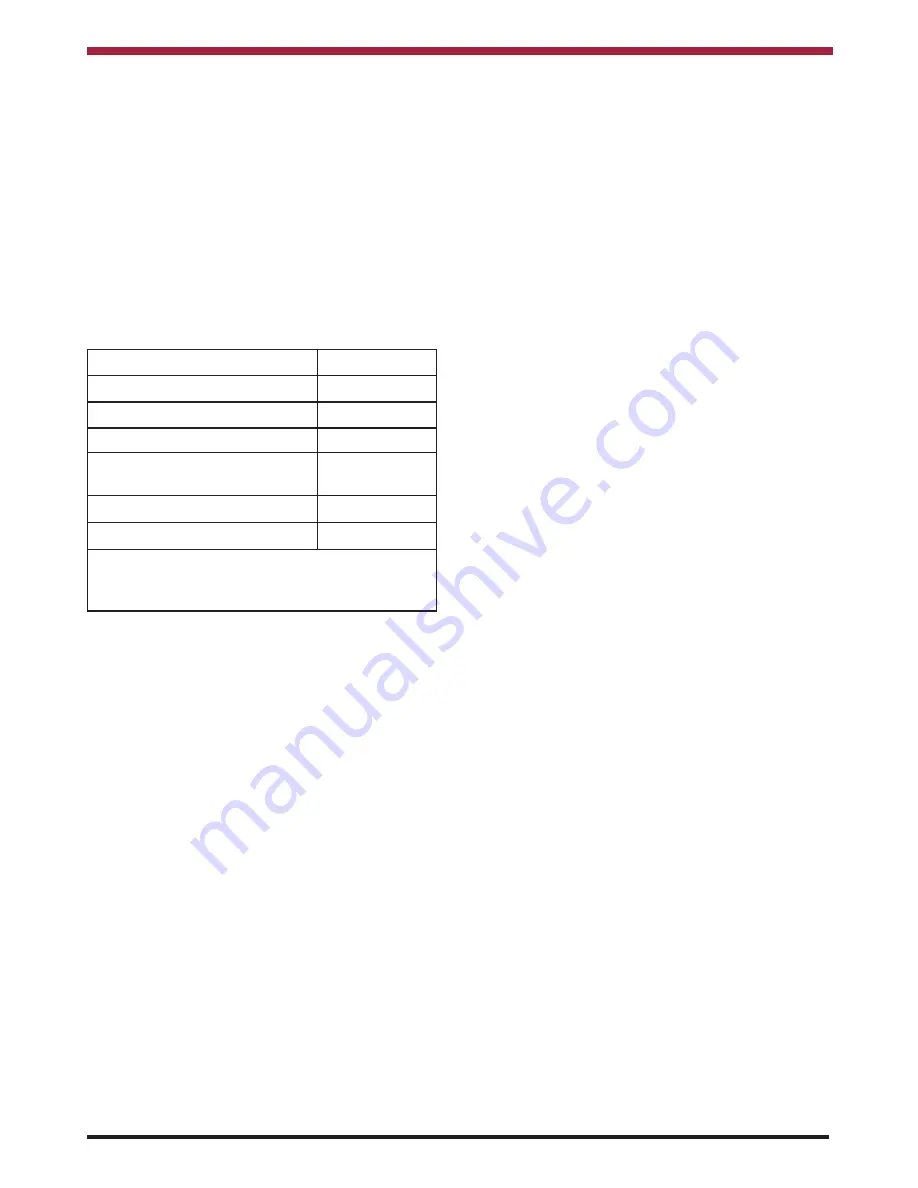

INSTALLATION CLEARANCES

Maintain at least the following clearances to all

combustible material:

VENTILATION & COMBUSTION AIR

REQUIREMENTS

It is imperative that there is sufficient air supply to

the stove in order to support correct combustion.

The air supply to this appliance must comply with

current Building Regulations. If another air using

appliance is fitted in an adjacent room it will be nec-

essary to calculate an additional air supply.

All materials used in the manufacture of air vents

should be such that the vent is dimensionally stable,

corrosion resistant, and no provision for closure.

The effective free area of any vent should be ascer-

tained before installation. The effect of any grills

should be allowed for when determining the effective

free area of any vent.

Air vents direct to the outside of the building should

be located so that any air current produced will not

pass through normally occupied areas of the room.

An air vent outside the building should not be locat-

ed less than the dimensions specified within the

Building Regulations from any part of any flue termi-

nal. These air vents must also be satisfactorily fire

proofed as per Building Regulations.

Air vents in internal walls should not communicate

with bedrooms, bedsits, toilets, bathrooms or rooms

containing a shower.

Air vents traversing cavity walls should include a

continuous duct across the cavity. The duct should

be installed in such a manner as not to impair the

weather resistance of the cavity.

Joints between air vents and outside walls should be

sealed to prevent the ingress of moisture. Existing

air vents should be of the correct size and unob-

structed for the appliance in use. If there is an

extraction fan fitted in adjacent rooms where this

appliance is fitted, additional air vents will be

required to alleviate the possibility of spillage of

products of combustion from the appliance/flue

while the fan is in operation.

Where such an installation exists, a test for spillage

should be made with the fan or fans and other appli-

ances using air in operation at full rate, (i.e.extrac-

tion fans, tumble dryers) with all external doors and

windows closed.

If spillage occurs following the above operation, an

additional air vent of sufficient size to prevent this

occurrence must be installed.

PERMANENT AIR VENT

The stove requires a permanent and adequate air

supply in order for it to operate safely and efficiently.

In accordance with current Building Regulations the

installer will have fitted a permanent air supply vent

into the room in which the stove is installed to pro-

vide combustion air. This air vent should not under

any circumstances be shut off or sealed.

Extractor Fan

There must not be an extractor fan fitted in the same

room as the stove as this can cause the stove to

emit smoke and fumes into the room.

7

From the Front

910mm (36”)

From the Back

450mm (17

3

/4

”)

From the Sides

575mm (22

1

/2

”)

From the Flue Pipe

575mm (22

1

/2

”)

From the Back (Horizontal

Installation only)

450mm (17

3

/4

”)

Mantle Clearance

700mm (27

1

/2

”)

Side Trim Clearance

450mm (17

3

/4

”)

Brick wall minimum clearance, but allow access

for controls and servicing. See Figs

10,11,12,13,14.