14

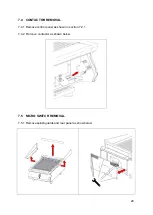

3.1.7 Clean the pan with warm water and detergent.

3.1.8 To clean the drip tray remove it from the appliance and warm water and detergent.

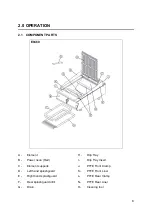

3.1.9 The splash guard is removable for cleaning.

3.1.10 The front and rear element support bars are also removable for cleaning.

3.1.11 To lower elements disengage locking pin and lower as required.

DO NOT USE COARSE ABRASIVES TO CLEAN EXTERIOR

PANELS. WARM WATER AND DETERGENT SOLUTION IS

RECOMMENDED.

DO NOT FORCE ELEMENTS DOWN WHILST LOCKING PIN

IS ENGAGED.

Summary of Contents for E9460

Page 18: ...18 6 0 INSTALLATION ELECTRICAL SAFETY AND ADVICE REGARDING SUPPLEMENTARY ELECTRICAL PROTECTION...

Page 31: ...31 7 7 CIRCUIT DIAGRAMS 7 7 1 E9490 Circuit Diagram...

Page 32: ...32 7 7 2 E9460 Circuit Diagram...

Page 33: ...33 7 8 WIRING DIAGRAMS 7 8 1 E9490 Wiring Diagram...

Page 34: ...34 7 8 2 E9460 Wiring Diagram...