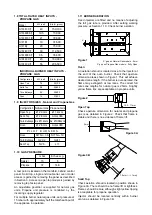

3.8.3 Gas Taps (Cleaning & Greasing)

Note

Plugs and bodies are machined as matching pairs

and are non-interchangeable. To avoid mix-up, clean

one tap at a time.

a) Remove top facia panel (see Section 3.2.4).

b) Remove fixings from tap body front. Withdraw

spindle and niting arrangement to allow plug to be

eased out.

c) Clean plug and body with a soft rag and re-grease

with an approved high temperature lubricant.

Apply grease sparingly, DO NOT block the gas

passageways of plug and body.

d) Ensure that plug is inserted into body in correct

position for operation.

e) Secure end cap to body. Note that fixing holes line

up in one way only.

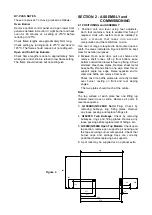

3.9 GOVERNOR (Natural Gas Appliances Only)

The type of governor supplied is maintenance-free.

Check that blue dust cap covering vent is fitted and in

good condition as this protects the breather hole.

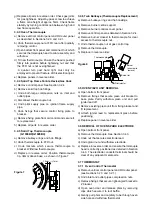

SECTION 4 - SPARE PARTS

When ordering spares, always quote unit type and

serial number. This information can be found on the

data plate, attached to the appliance.