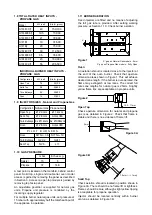

894

680

185

140

257

317

829

879

15

60

200

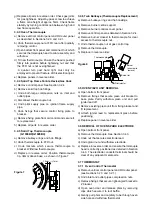

BY-PASS RATES

These are pre-set. To check, proceed as follows:-

Oven Burner

Remove vertical control panel and open lower front

panel as detailed in Section 3. Light burner and heat

oven for 45 minutes at a setting of 275

o

C before

reducing to 125

o

C.

Check flame lengths are approximately 5mm long.

Check setting by turning knob to 275

o

C and back to

125

o

C. The flame should reduce but not extinguish.

Open and Solid Top Burners

Check flame lengths reduce to approximately 5mm

when gas control knob is turned to low flame setting.

The flame should reduce but not extinguish.

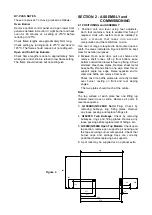

Figure 4

SECTION 2 - ASSEMBLY and

COMMISSIONING

2.1 POSITIONING and ASSEMBLY

1. Position unit and level using feet adjusters.

Each foot contains a hole to enable floor fixing if

required. Units with castors must be installed in

such a manner that takes into account

manipulation and the restrictions on site.

If an oven or range is required to be mounted upon a

plinth, the areas indicated in Figure 4 MUST be kept

clear for aeration purposes.

2. Ovens: Open oven door, pull out shelves and

remove shelf runner. Lift up from bottom, ease

bottomoutward and lower to free top fixing. Lift out

stainless steel base plates. Remove sheet metal

base baffle, lift and slide to one side. Rest this on

support angle top edge. Raise opposite end to

clear side baffle and remove from oven.

Check cast iron baffle plates are correctly located

over burner, resting on front and rear sloping

angles.

The two plates should touch at the centre.

Note

The top surface of each plate has one lifting lug

directed toward oven centre. Replace all parts in

reverse sequence.

3. G1006BX/G1026BX Solid Top: Check by

removing bullseye, ring, filling plates. Remove

any loose packing and replace fillings etc.

4. G1006FX Twin Bullseye: Check by removing

bullseyes, rings and filling plates. Remove any

loose packing before replacement of fillings, etc.

5. G1006X/G1066X Open Top Models: Check open

top section, remove pan supports, all packing and

the tape securing burner components. Check that

burner caps and spillage trays are correctly

positioned before replacing pan supports.

6. A pot rack may be supplied as an optional extra.