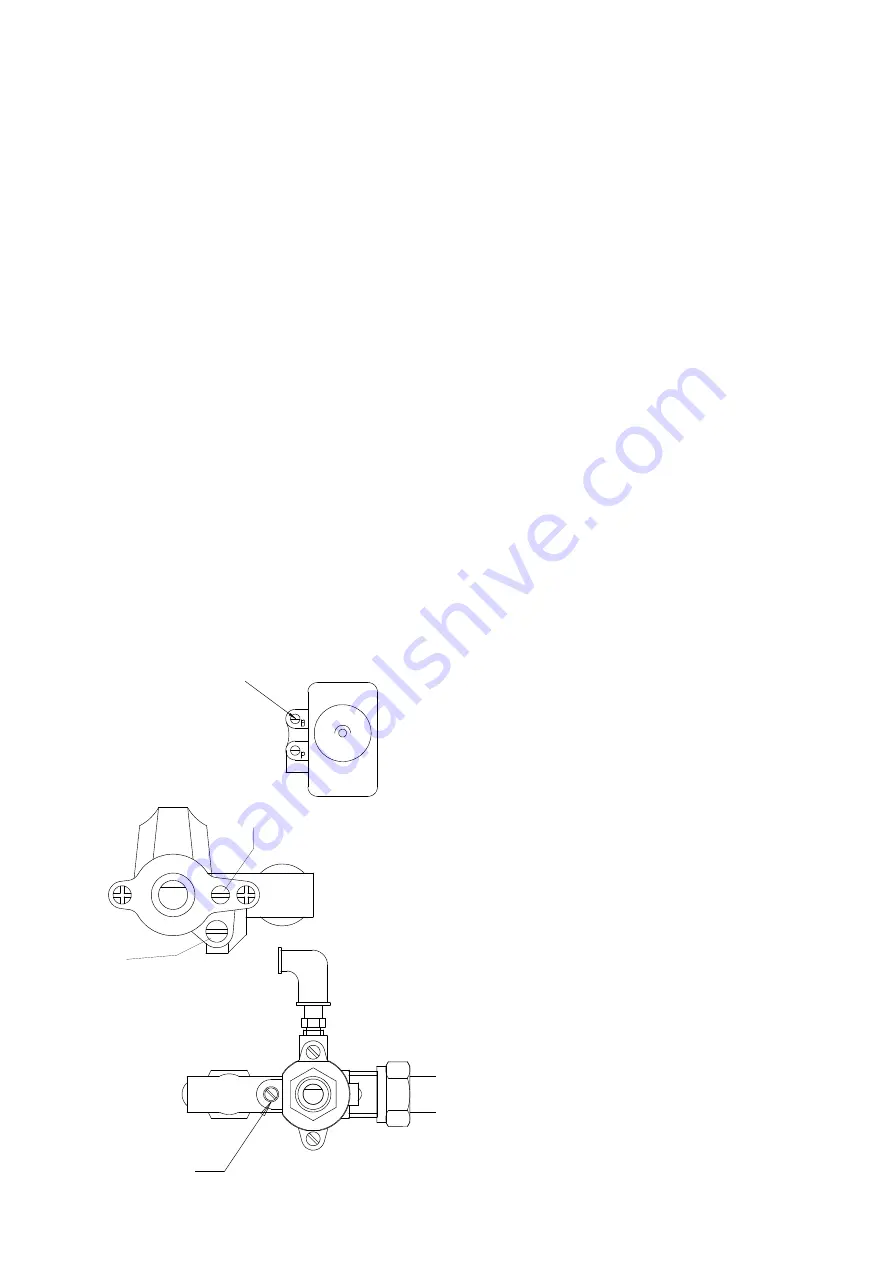

Oven thermostat bypass screw

Pilot

(Solid Top Only)

Bypass screw

Low flame

adjustment

f) Remove right-angled bracket from existing

thermostat and fit it to replacement.

g) Replace all parts in reverse order and check gas

joints for tightness.

3.7.2 To Check and Adjust the Thermostat

a) Remove control panel as detailed in Section 3.2.3.

b) Replace knob and turn to 200

o

C position. This

should be the temperature at this setting.

c) Place a temperature measuring device at

geometric centre of oven and light oven.

d) Allow oven to heat up for 30 minutes. Observe

temperature is steady. Compare value obtained

with required value of 200

o

C.

Example - Oven at 190

o

C.

Action

Turn knob to a higher setting until a temperature of

200

o

C+/-5

o

C is obtained. Pull knob off without

rotating spindle. Undo fixings on adjusting flange at

spindle base. Replace knob and turn it back to 200

o

C

setting. Remove knob and tighten adjusting flange

fixings. Check temperature remains steady at new

setting for 200

o

C.

Reverse action if oven temperature is above or below

200

o

C.

e) Turn thermostat to lowest setting and adjust

by-pass screw to achieve flame cone length of

approximately 5mm. Check flame stability as

detailed in Section 1.11.

Figure 9

3.8 GAS TAPS and FFD

3.8.1 Replacement Taps for Open Top and

Solid Top Burners (G1006BX/G1026BX)

a) Remove control panel as detailed in Section 3.2.4.

b) Remove hob lift-off components.

c) Undo inlet/outlet pipe compression nuts.

d) Disconnect thermocouple nut.

For solid top units, proceed with e) to g).

e) Undo pilot supply pipe.

f) Undo fixings that secure control location plate to

bracket.

g) Remove fixing plate from previous control and

secure to replacement.

Replace parts in reverse order.

Also check FFD thermocouple position at low flame

operation. Check open top flame stability on low

flame settings by turning control between high and

low settings.

To set by-pass rate: Aimfor flame cone lengths of

approximately 5mm. Typically, this may be achieved

by withdrawing by-pass screw fromits closed position

by:

Open Top

Natural Gas - Half turn

Propane Gas - Quarter turn

Solid Top

Propane Gas - Two Turns

3.8.2 Twin Bullseye

a) Remove bullseye rings and hob castings.

b) Remove centre support.

c) Remove burner control panel.

d) Remove control panel as detailed in Section 3.2.4.

e) Undo saddle clamp plate to float rail.

f) Unscrew burner assembly and manifold bracket

fromside panel and crown plate.

g) Remove burner assembly c/w with gas tap and

manifold bracket to gain complete access to

pipework.

h) Remove pilot pipe, main feed pipe and

thermocouple nut from tap.

j) Remove pilot pipe adaptor from gas tap.

k) Replace components in reverse order.

m) Replace all parts in reverse order.