5

1.6 TOTAL RATED HEAT INPUTS

Natural (I

2

H)

and

Propane (I

3

P) Gas

22kW

(net),

82,500 btu/hr

(gross).

SECTION 2 - ASSEMBLY and

COMMISSIONING

The gas supply piping and connection to appliance must be installed in accordance with the various regulations

listed on the cover of this manual.

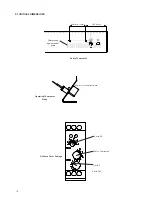

2.1 ASSEMBLY

a) Unpack appliance

b) Unpack fryer baskets and accessories.

c) Place basket support grid and basket in pan.

d) Level appliance and fit all service protection kits.

(Anti-tilt kit, if ordered as accessory)

.

2.2 CONNECTION TO A GAS SUPPLY. (also refer to section 1.4 above)

Connect gas supply and test for gas tightness.

Caution

-

Ensure that pan contains an acceptable level of liquid before igniting burner.

If you are in the fat melting cycle <<fat melting cycle>>

(FMC)

and loading solid fat for the first time, always

remove basket support plate as detailed in Section 9. Solid fat should be in direct contact with fryer pan.

Refer to Section 9.

Due to the presence of mains electrics, integral pipe work should be checked for gas tightness using an appropriate gas

leak detector.

Caution

- Installation engineers should note that for first time connection of appliance to supply,

it is essential

that inlet

gas supply to fryer is completely purged of air prior to first lighting attempt. Otherwise initial lighting attempts may fail,

resulting in burner reset switch having to be used. This should not initially be treated as a fault.

Please note that several attempts will still be required after air purge to fryer for first time lighting. This is due to

capacity of valve and governor.

2.3 CONNECTION TO AN ELECTRICAL SUPPLY. (also refer to section 1.5 above)

Ensure flexible cable does not come into contact with any hot parts. The fuse rating should be 13A.

The colour codings of power supply cables are as follows: Live - Brown, Neutral - Blue, Earth - Green/Yellow

2.4 STARTING UP

If you are in the fat melting cycle <<fat melting cycle>>

(FMC)

and loading solid fat for the first time, always

remove basket support plate as detailed in Section 9. Solid fat should be in direct contact with fryer pan.

Refer to Section 9.

Summary of Contents for G2844F

Page 25: ...25 SECTION 11 G2844F CIRCUIT DIAGRAM...

Page 26: ...G2845F CIRCUIT DIAGRAM...

Page 27: ...27 G2844F WIRING DIAGRAM...

Page 28: ...G2845F WIRING DIAGRAM...