2

Ignition electrode

Thermocouple

Outline of burner

Burner ports

4.0

4.5

4.0

4.5

3.4 INJECTORS

3.4.1 Open Top

Remove pan support and burner head.

Undo and remove brass venturi. Place an extended

socket down main burner body centre.

Undo injector and carefully remove it.

Replace in reverse order.

3.4.2 Oven andSolidTop

Injectors are accessible for removal upon removal of

the burners.

3.5 FLAME FAILURE DEVICE

3.5.1 Oven

To remove, proceed as follows -

a) Remove oven burner as described in Section

3.3.3.

b) Undo union nut that secures gas supply pipe to

flame failure device at front of unit.

c) Undo fixings which secure injector bracket to base

panel and lift assembly clear.

Flame failure device embodies a thermocouple

heated directly by burner flame, i.e. no pilot is used.

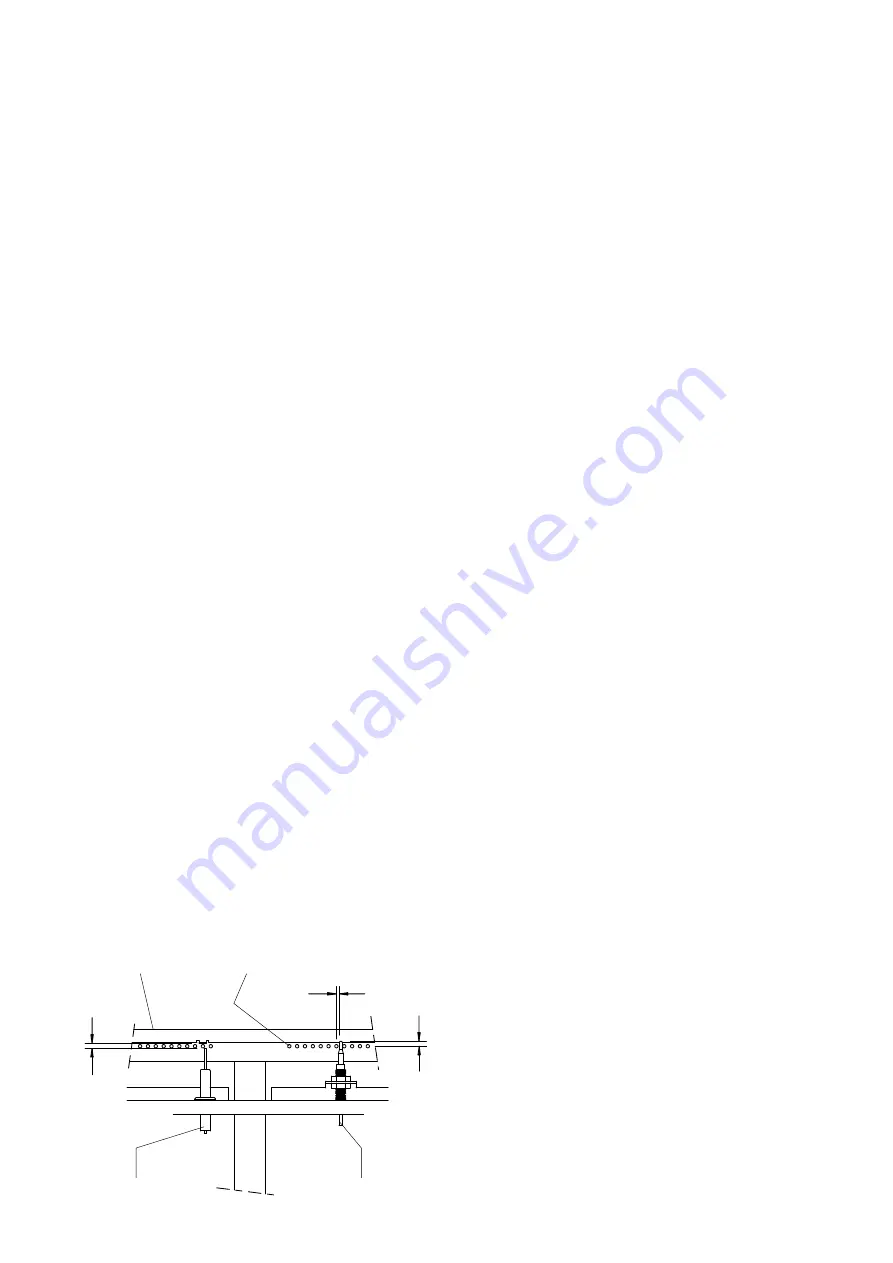

The correct relationship between thermocouple probe

and burner is shown in Figure 4. When FFD button is

pressed to light burner, gas is admitted to burner at a

reduced rate. When thermocouple probe is

sufficiently heated to enable FFD to become

energised, full gas rate will flow upon release of

button.

3.5.2 Open Top

Remove hob pan supports and burner heads to allow

access to brass venturi. Undo venturi and remove

with aluminium bezel.

Thermocouple can now be observed protruding

through dripshed. Undo dripshed fixings and

remove.

Burner support bracket is located directly below drip

shed. Remove nut that secures thermocouple to

bracket and pull through from underside.

Undo thermocouple connection at FFD section of gas

tapand carefully remove thermocouple from hob.

Replace in reverse order.

3.5.3 SolidTop

Flame failure thermocouple is part of pilot assembly.

See Section 3.3.4.

3.6 SPARK IGNITER

To remove, proceed as follows:

a) Remove oven grid shelves and base plate.

b) Remove FFD and igniter cover.

c) Remove igniter lead and from inside, undo nut that

secures igniter.

Replace in reverse order. Check oven burner ignites

from spark. If spark-gap adjustment is necessary,

refer to dimensions in Figure 5.

3.7 OVEN THERMOSTAT

3.7.1 Thermostat Replacement

To remove, proceed as follows -

After removing control panel, undo compression nut

on gas supply pipe at thermostat rear.

Undo fixings that secure thermostat. Free thermostat

sensor from oven roof clips and feed capillary tube

and sensor back through roof hole into upper

compartment. Thermostat can now be removed from

unit.

N.B. Replace in reverse order, always ensuring that a

new gasket is used and joints are tested for gas

soundness

3.8 GAS TAPS

3.8.1 Open Top

Remove control panel as detailed in Section 3.2.

To Service

Undo tapbody fixings and withdraw spindle and niting

arrangement to allow plug to be eased out.

Replace in reverse order.

To Remove

Undo compression fitting brass nut on supply pipe at

rear of gas tap.

Remove thermocouple connection from FFD section

of tap.

Undo fixings and gently remove tap from supply

manifold.

To Clean andRe-grease a Tap

Dismantle tapby removing single front retaining

screw then push in and rotate spindle anti-clockwise

until niting pin is free. Withdraw spindle and centre

plug, taking care not to lose the small compression

spring. Clean all parts with a soft rag, and sparingly

re-grease plug with an approved high temperature

grease is recommended. Also apply grease to

operating spindle where it enters plug.

Note

Tap plugs and bodies are made in matched pairs -

DO NOT INTERCHANGE.

All manuals and user guides at all-guides.com