13

d) Once desired time is reached, press P key to

accept/enter.

e) The display will now alternate between “PrEz” and

“X:XX” where z is the number of key presses and

X:XX is action alarm time in minutes and seconds.

NOTE: The time entered here is the time action is

required before the end of the total cycle time entered

above. If NO Action time is required, leave at “0:00”.

Adjust time as c) above.

f) Once desired time is reached, press P key to

accept/enter.

g) “Prog” will again be displayed and another product

key can be selected for programming. Repeat above

steps. When no more keys are required to be

programmed and “Prog” is displayed, press P key to

exit programming mode and return to idle mode.

SECTION 7 -

CHANGING/FILTERING THE OIL

Warning

After filtering, wait 30 seconds before removing bucket.

It is dangerous to use shortening that is too old.

This medium has a reduced flash point temperature and

is prone to surge boiling.

Caution

To prevent surge boiling. DO NOT EXCEED

recommended loads or charge the pan with over-wet food

items. NEVER LEAVE a working appliance unattended.

Warning

When draining solids/shortening, ensure oil has time to

strain through strainer basket. Heavily unfiltered oil may

overflow.

Note

This could cause pump to block over a period of time and

is considered as misuse of equipment.

Warning

When pumping solids/shortening back into fryer pan.

Ensure all trace of solids/shortening is emptied from

receptacle (bucket).

If oil is not emptied on a regular basis or if oil is left in the

receptacle, it may solidify and overflow or spill on to the

kitchen floor to create a hazard.

7.1 STARTING THE FILTRATION PROCESS

1. Turn burner & temperature controls ON/OFF switch to

OFF position and allow oil to cool below 170°C

(or if cold, heat to minimum temperature of 60°C).

Open cabinet door and pull filter bucket forward.

2. Ensure bucket is clean and emptied of all solid/

shortening and debris. Refer to Section 8 for details of

how to clean filter components.

3. Ensure that strainer and microfilter are clean.

4. With strainer and microfilter in position, slide bucket

back on to runner cradle and back into fryer.

Please Note - Warning

Do not handle filter components or adjacent surfaces

when pump is operating.

Components will remain hot for a period after filter.

Allow cooling. Use of PPE's is recommended.

Note: Burner and temperature controls ON/OFF switch

must be in OFF position before operation of filter pump

can begin.

7.2 G401F and G402F MODELS

1. Press filtration pump switch to turn on pump.

Note: With cabinet door open, switch is located at

RH side of drain valve (Refer to Figure 4).

2. Turn drain handle clockwise.

3. Pan will drain through strainer basket and microfilter

into bucket and will pump back into pan.

4. Clear debris from pan.

5. If pan drain becomes blocked, clear using drain prod.

6. When debris has been removed from pan, turn valve

handle anti-clockwise to close valve.

7. Allow pan to refill.

8. If any solid/shortening remains, repeat Step 1.

Warning

Ensure all shortening has been pumped from receptacle

before topping up pan.

9. Switch filtration pump off.

10. Top up fryer if required.

Summary of Contents for G402F

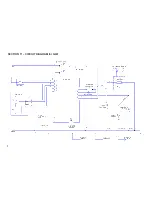

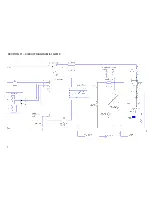

Page 16: ...SECTION 11 WIRING DIAGRAM for G401 16...

Page 17: ...SECTION 11 WIRING DIAGRAM for G401F 17...

Page 18: ...SECTION 11 WIRING DIAGRAM for G402 18...

Page 19: ...SECTION 11 WIRING DIAGRAM for G402F 19...

Page 20: ...SECTION 11 CIRCUIT DIAGRAM for G401 20...

Page 21: ...SECTION 11 CIRCUIT DIAGRAM for G401F 21...