SECTION 1 - INSTALLATION

UNLESS OTHERWISE STATED, PARTS

BEEN PROTECTED BY THE MANUFACTURER

NOT TO BE ADJUSTED BY THE INSTALLER.

Please ensure that any plastic coatings are

to use. Before operation, pan requires

cleaned and dried.

Discolouration of heated parts is caused

testing to ensure a satisfactory unit. It

quality or performance.

1.1 MODEL NUMBERS, NETT WEIGHTS

and DIMENSIONS

Model

Width

(mm)

Depth

(mm)

G401F Fryer

400

840

G402F Fryer

400

840

Pan oil capacity:

18 litres cold, good quality oil (to - MIN

1.2 SITING

The unit must be installed on a firm, level

lit draught free position. The fryer should

in a position where the possibility of sideways

likely when force is applied. The means

be the manner of installation, such as

a battery of appliances or installing the fryer

or by separate means, such as adequate

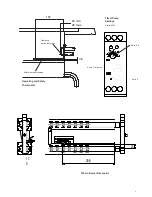

1.2.1 Anti-tipping Accessory

An anti-tipping mechanism is also

accessory. If these are to be fitted, the brackets

fitted to locate the fryer in the correct position

any walls as detailed below. Fixing holes are provided in

the fryer base to accommodate the bracket.

should be fitted as detailed in Figure

chain has a quick release eyelet. Secure

and secure bracket to floor after

anti-tipping device attached to the fryer.

below floor bracket.

Figure 1 - Anti-tipping Bracket

TION

TS WHICH HAVE

MANUFACTURER ARE

INSTALLER.

are removed prior

to be thoroughly

caused by factory

It does not affect

WEIGHTS

Height

(mm)

Weight

(kg)

1200

94

1200

94

MIN - mark)

level floor in a well-

should not be installed

sideways tipping is

means of restraint may

as connection to

fryer in an alcove,

as adequate ties.

available as an

brackets must be

position relative to

holes are provided in

bracket. The bracket

1. The retaining

Secure to fixing point

alignment with

fryer. Adjust to slide

Bracket

1.2.2 Clearances

The unit requires a clearance

between unit and any combustible

A minimum vertical clearance

allowed between top edge

overlying combustible surface.

Important

If fryer is to be installed with

instructions for every model

determine the necessary clearance

wall or overlying surface.

Some appliances require greater

than others. The largest

determine overall distance

adjoining appliances.

1.3 VENTILATION

The appliance ventilation requirements

with national and local regulations.

The ventilation rate for these

The appliance flue discharges

There must be no direct connection

mechanical extraction system

should be installed under a ventilated

Adequate ventilation, whether

be provided to ensure sufficient

and for removal of combustion

harmful to health.

For multiple installations, requirements should

together. Installations should

local and/or national regulations

A competent engineer must

work.

1.4 GAS SUPPLY (Both models)

To be checked at installation,

The SIT gas valve, situated

accessible by removing RH

governor. The inlet pressure

inlet test nipple using a manometer

should be set at test nipple on burner

means of a manometer as

Page 4 (for either natural

achieved by removing brass

governor and adjusting governor

screwdriver - clockwise rotation

Note: Propane requires governor

clockwise to maximum adjustment.

3

clearance of at least 150mm to rear

combustible wall.

clearance of 750mm should be

edge of flue outlet and any

surface.

with other appliances then the

model should be consulted to

clearance to any combustible

greater clearance distances

largest clearance will therefore

for a complete suite of

requirements should be in line

regulations.

these models is 26m³/min.

discharges vertically from top of unit.

connection of flue to any

system or outside air. The fryer

ventilated canopy.

whether natural or mechanical must

sufficient fresh air for combustion

combustion products which may be

requirements should be added

be made in accordance with

regulations applying at the time.

be used for any installation

models)

at installation, gas conversion or repair.

at rear RH side of unit and

RH side, has an in-built

should be checked at valve

a manometer and burner pressure

on burner manifold, again by

as per values indicated on

or propane gas). This is

brass dust screw from valve

governor accordingly using a

rotation increases pressure.

governor to be adjusted

adjustment.

Summary of Contents for G402F

Page 16: ...SECTION 11 WIRING DIAGRAM for G401 16...

Page 17: ...SECTION 11 WIRING DIAGRAM for G401F 17...

Page 18: ...SECTION 11 WIRING DIAGRAM for G402 18...

Page 19: ...SECTION 11 WIRING DIAGRAM for G402F 19...

Page 20: ...SECTION 11 CIRCUIT DIAGRAM for G401 20...

Page 21: ...SECTION 11 CIRCUIT DIAGRAM for G401F 21...