6

3

1

2

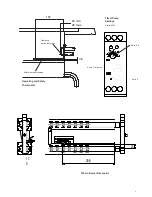

Figure 4 – G401F & G402F - Additional

3. Burner Lock-Out Reset Switch

Resets burner for further lighting attempts,

lockout indicator is illuminated.

4. Filtration Pump Switch

Energises filtration pump when burner

OFF (O) position.

5. Temperature Safety Limiter Reset Button

Inside red recess.

2.4.4 G401F Controller Diagnostic Indicators

(On printed circuit board of controller,

behind control panel)

Green LED ‘ON’ indicates heat demand.

Green LED ‘OFF’ indicates no heat demand.

Red LED flashes if temperature probe

open circuited.

Red LED is permanently ‘ON’ to indicate

Set point is +/-7

⁰

C of mid-set point.

2.5 PRE-COMMISSIONING CHECK

1. Clean out pan thoroughly using

detergent. Rinse out and dry thoroughly.

Note

For further detail with regard to cleaning,

Section 8.

2. Ensure drain valve is closed. Fill

cooking oil to - MIN - (maximum

indicated on basket hanging rail. (See

Note: MAX refers to maximum hot fill

3. With gas supply still shut off, turn on electrical

supply.

4. Open door and press temperature

reset button (red), refer to Section

switch to Position 'I' (ON position).

5. Turn control knob to desired temperature

(G401F only) and heat demand

illuminate (Figure 2, item 4).

4

6. G402F is factory preset for

(See Section 6.3 - how to

7. Fryer ignition sequence

may be heard before unit

Note: Ignition system will

14 seconds after completion

5

Additional Controls

attempts, when burner

burner switch is in

Button

Indicators

On printed circuit board of controller,

demand.

demand.

is either short or

indicate system is OK.

hot water and

thoroughly.

cleaning, refer to

pan with clean

(maximum cold fill mark)

(See Figure 5).

fill mark.

on electrical mains

temperature limit thermostat

Section 2.6. Set burner

temperature (140

⁰

C)

demand indicator will

detected during first attempt.

2nd attempt).

8. The neon next to burner

illuminate to indicate that

that no burner flame

Additional controls - Item

9. Turn gas supply on.

10. Press lockout reset switch.

indicator will extinguish).

11. Burner will ignite and heat

signify that burner is on.

If lockout should occur, repeat

bled from supply and burner

12. When burner flame is established,

leaks. Care should be taken

is present. Isolate after gas

2.5.1 Checking Controller Operation

To check operation of controls,

Controller - Section 6.2.3.

2.5.2 Checking Oil Filtration

To check operation of pump,

Important

After installation, the responsible

for gas leaks and ensure the appliance

and satisfactorily before handing over

2.6 TEMPERATURE LIMIT THERMOST

The unit is equipped with an

thermostat, independent of the

In the case of operating thermostat

temperature to rise above predetermined

zone (230

⁰

C), limit device will

controller. It will also stop the

To re-set temperature limit thermostat,

G401F and G402F Models

a) Turn burner and temperature

to OFF position.

b) Allow oil to cool below 180

c) Reset red button on limit

similar item. The button is

at upper RH, below facia panel.

for a temperature of 180

⁰

C

to change set temperature).

will commence and spark

before unit locks out.

will try a second sequence

of first attempt if no flame is

(Unit will only lock out after

burner switch inside door will

that lockout has occurred and

is present. G401F/G402F

Item 2 on Figure 4.

switch. See Figure 4 (Lock out

heat indicator will illuminate to

repeat Steps 10 -11 until air is

lights.

established, check for gas

taken because mains voltage

after gas checks.

Operation

controls, refer to Using The

Filtration Pump

of pump, refer to Section 7.

responsible technician should check

appliance is operating safely

handing over to the user.

THERMOSTAT

additional temperature limit

the main controller.

thermostat failure, allowing oil

predetermined legislation safe

will activate and cut power to

the flow of gas to burner.

thermostat, refer to Figure 4.

temperature controls ON/OFF switch

180

⁰

C

limit thermostat with a pen or

located behind cabinet door

panel.

Summary of Contents for G402F

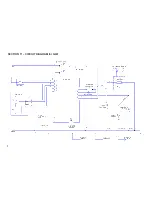

Page 16: ...SECTION 11 WIRING DIAGRAM for G401 16...

Page 17: ...SECTION 11 WIRING DIAGRAM for G401F 17...

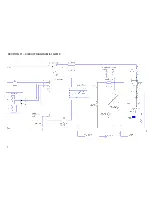

Page 18: ...SECTION 11 WIRING DIAGRAM for G402 18...

Page 19: ...SECTION 11 WIRING DIAGRAM for G402F 19...

Page 20: ...SECTION 11 CIRCUIT DIAGRAM for G401 20...

Page 21: ...SECTION 11 CIRCUIT DIAGRAM for G401F 21...