SECTION 1 - INSTALLATION

1.2 SITING

The unit must be situated on a reasonably level

surface. Although the feet are adjustable and facil-

itate levelling, the adjustment range is limited.

Installation must be executed in accordance with

local and/or national regulations, as listed on the

cover of this manual. A competent installer must be

employed.

Installing Clearances

At least 150mm must be allowed from any wall.

To facilitate servicing, it is recommended that a space

of at least 400 mm should be allowed from any side

wall. If the unit is beinginstalled as part of a suite, it is

further recommended that it be positioned at the RH

end to provide unrestricted access for servicing.

A minimum vertical clearance of 750mm must be

allowed between the top edge of the flue outlet and

any overlyingsurface.

If unit is to be installed in a suite, centrally or adjacent

to a wall with a boxed in void at the rear, it is vitally

important that the void be adequately ventilated.

This will ensure a supply of air to the motor cooling

fan at the rear of the oven.

1.3 VENTILATION

Adequate ventilation, whether natural or mechanical

must be provided to supply sufficient fresh air for

combustion and allow easy removal of combustion

products which may be harmful to health.

The flue discharges vertically from the slotted guard

at the top of the appliance. It must not be directly

connected to any flue, mechanical extraction system,

or ductingetc., which leads outside the building.

The appliance is best discharged under an open

canopy which connects with a ventilatingsystem.

Recommendations for Ventilation of Catering

Appliances are given in BS5440 : 2.

Furthermore, to ensure sufficent room ventilation,

guidance on the volume of ventilation air required for

different types of cateringequipment is provided in

the followingtable.

For multiple installations, the requirements for in-

dividual appliances should be added together. In-

stallation should be made in accordance with local

and/ or national regulations applicable at the time.

A competent installer MUST be employed.

1.4 GAS SUPPLY

The incomingservice must be of sufficient size to

supply full rate without excessive pressure drop. A

gas meter is connected to the service pipe by the

local gas region or its sub-contractor. Any existing

meter should be checked by the gas region to ensure

the meter is of adequate capacity to pass the required

rate of gas for the oven in addition to any other gas

equipment installed.

Installation pipe work should be fitted in accordance

with IGE/UP/2. The pipe should not be smaller than

the gas inlet connection on the appliance

i.e. Rp

1

/

2

(

1

/

2

" B.S.P.)

An isolatingcock must be located close to the

appliance to allow shut-down duringan emergency

or servicing. The installation must be tested for gas

soundness as specified in IGE/UP/1. The adjustable

governor supplied must be fitted in an accessible,

spillage-free and reasonably cool position.

1.5 ELECTRICAL SUPPLY

Each oven is equipped with a length of 3-core flexible

cord for connectingto an electrical supply. A standard

13 amp socket outlet can be used, in which case the

plug-top must be fitted with a 3 amp fuse. If the supply

is through a distribution fuse, box, it must be via a

fuse havinga maximum ratingof 5 amp.

Warning

THIS APPLIANCE MUST BE EARTHED.

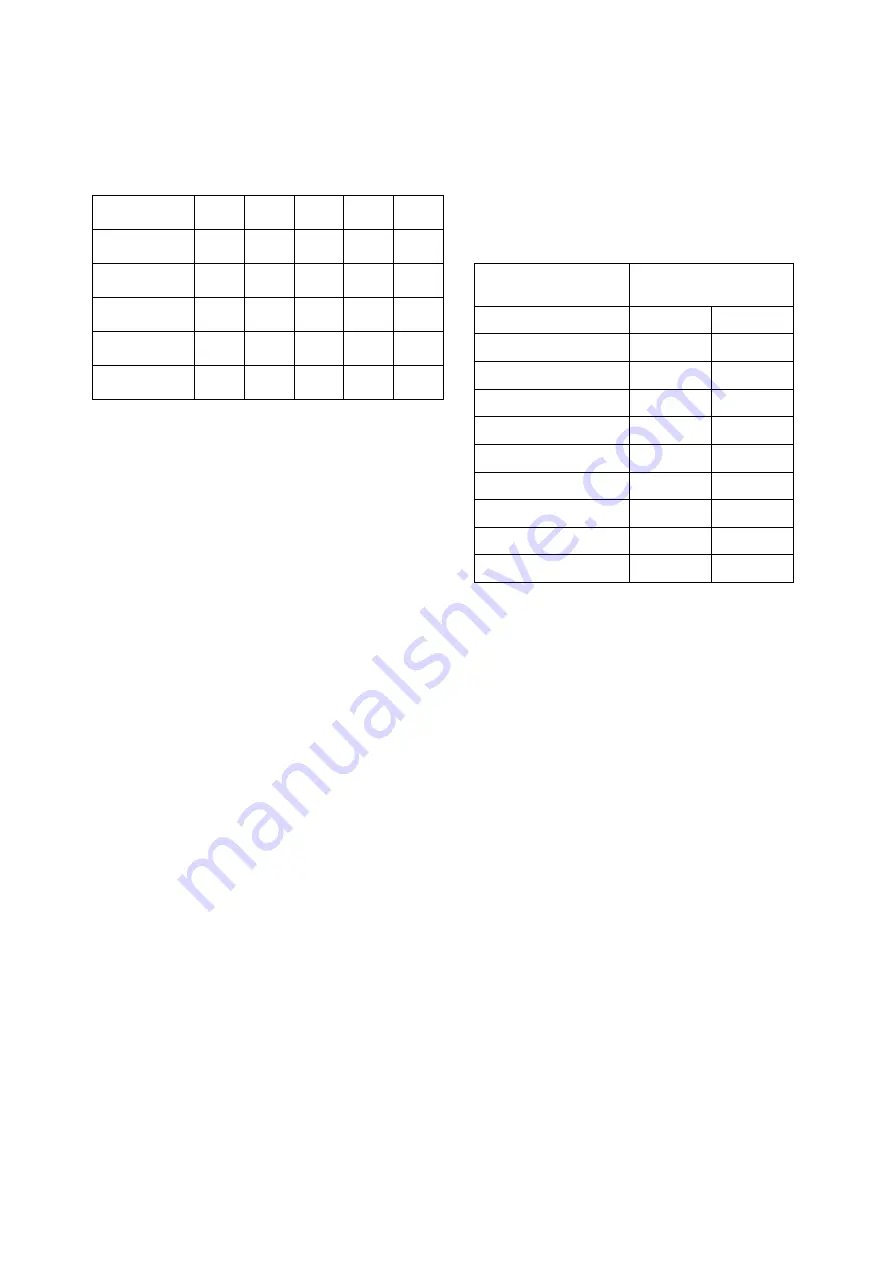

EQUIPMENT

Ventilation Rate Required

m

3

/ min

ft

3

/min

Range, Unit Type

17

600

Pastry Oven

17

600

Fryer

26

900

Grill

17

600

Steak Grill

26

900

BoilingPan

17

600

Steamer

17

600

SterilizingSink

14

500

Bains Marie

11

400

Tea/ Coffee Machine

8.5 - 14

300 - 500

UNLESS OTHERWISE STATED, PARTS WHICH HAVE BEEN PROTECTED BY THE MANUFACTURER

ARE NOT TO BE ADJUSTED BY THE INSTALLER

MODEL

WIDTH

mm

DEPTH

mm

HEIGHT

mm

WEIGHT

kg

WEIGHT

lbs

G7204

860

860

1400

170

375

G7208

1000

925

1525

220

484

G7211

1000

925

1525

232

512

G7211

TROLLEY

820

740

910

33

73

G7211

RACK/ SHELVES

710

560

830

37

82

1.1 MODEL NUMBERS, NETT WEIGHTS

and DIMENSIONS

All manuals and user guides at all-guides.com