9

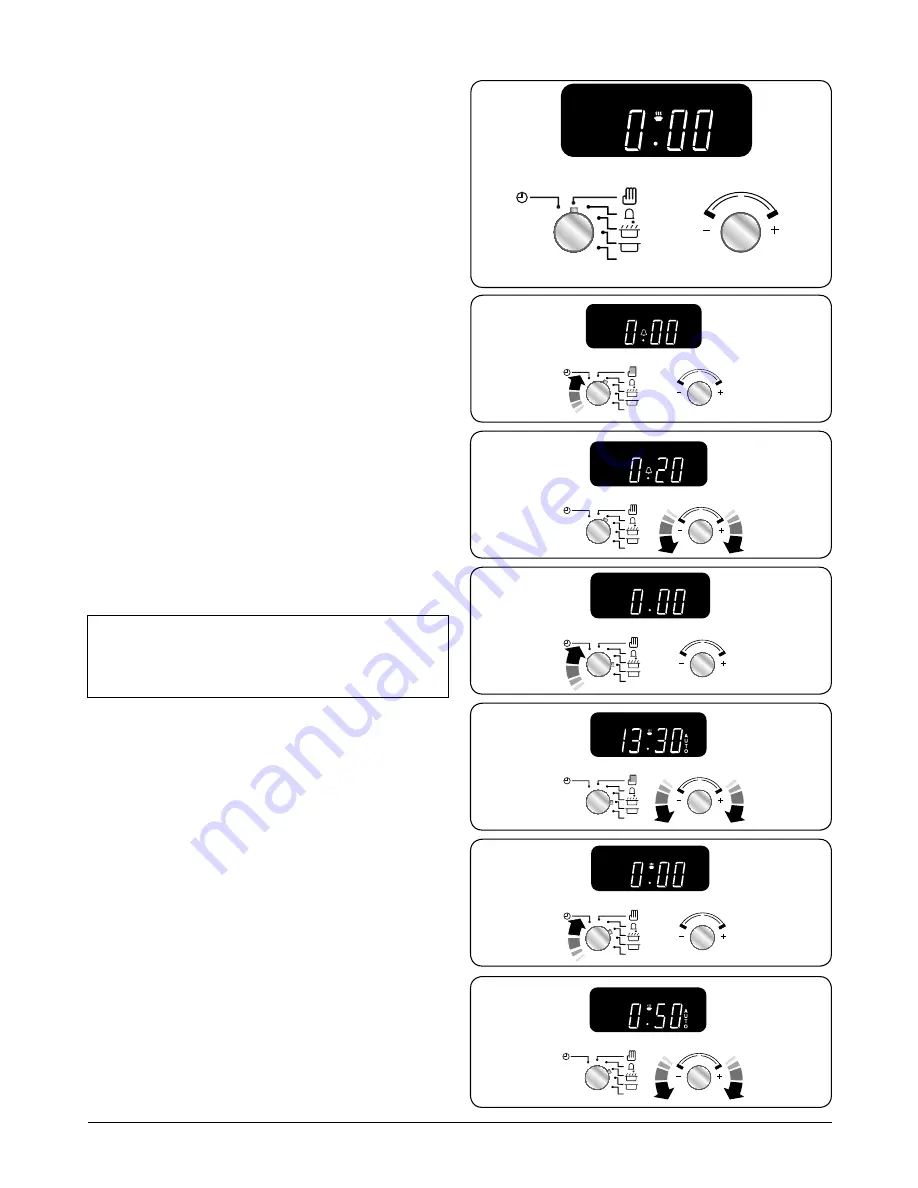

The Clock

You can use the clock to turn the right-hand oven on and off.

The clock must be set to the time of day before the oven

will work.

Note:

When using the timer functions, first set the clock as

required before setting the oven temperature.

Setting the Time of Day

The LCD clock is shown in

(Fig.2-22)

. When the clock is first

connected, the display flashes (

0.00

) and (

G

) alternately.

To set the time, turn and hold the Timer knob to the clock

symbol [

A

] and at the same time turn the Adjusting knob left

or right until the clock shows the time of day. Remember this

is a 24-hour clock. Let go of the Timer knob and it will spring

back to the vertical, oven manual setting.

IMPORTANT:

The right-hand oven will not operate unless

the clock has been set.

Setting the Minute Minder

To activate the minute minder turn the Timer knob to the

right to the [

C

] minute minder setting – it should click into

position

(Fig.2-23)

.

Rotate the Adjusting knob to set the time required

(Fig.2-24)

.

You can either turn the knob back to the vertical manual

setting [

B

] to keep an eye on the time of day, or leave it in

the [

C

] minute minder position as the time ticks down.

To stop the beeper when it sounds, turn the Adjusting knob

counter-clockwise.

•

The

‘cook period’

, which is the length of time you

want the oven to cook for.

•

The

‘stop time’

, which is the time of day you want the

oven to stop cooking.

To Stop the Right-hand Oven at a Specific Time of Day

Turn the Timer knob to the [

E

] position

(Fig.2-25)

.

Use the Adjusting knob to set the

‘stop time’

. You can set

the oven to turn on at any time over the following 24-hour

period. AUTO shows in the display

(Fig.2-26)

.

Turn the Timer knob to the bottom ‘AUTO’ setting to return to

the clock display.

Once the

‘stop time’

is reached, the beeper sounds. Turn the

Timer knob to the vertical [

B

] to return to manual cooking.

To Start and Then Stop the Right-hand Oven Using the

Timer

You cannot set a start time directly – this is set

automatically by a combination of the

‘cook time’

and

‘stop time’

.

Turn the Timer knob to the [

D

] position

(Fig.2-27)

.

Turn the Adjusting knob to set the

‘cooking time’

you need

(Fig.2-28)

.

ArtNo.300-0004 2-button clock annotated

A

B

AUTO

A – Timer knob, B – Adjusting knob

Fig.2-22

AUTO

ArtNo.300-0006 2BC

minute minder setting 2

ArtNo.300-0004 2-button clock annotated

AUTO

AUTO

ArtNo.301-0008 2BC

Stopping the oven 2

AUTO

Fig.2-23

Fig.2-24

Fig.2-25

Fig.2-26

ArtNo.300-0004 2-button clock annotated

AUTO

ArtNo.301-0010 2BC

Setting the cooking time

AUTO

Fig.2-27

Fig.2-28

Summary of Contents for Hi-LITE 110

Page 1: ...Hi LITE 110 Dual Fuel USER GUIDE INSTALLATION INSTRUCTIONS ...

Page 4: ...ii ...

Page 36: ...32 Notes ...

Page 37: ...33 Notes ...

Page 38: ...34 Notes ...