WARNING – SERVICING TO BE CARRIED OUT ONLY BY AN AUTHORISED PERSON

Disconnect from electricity before servicing. Check appliance is safe when you have finished.

32

2 Hotplate

2.1 To Remove the Hotplate

DISCONNECT FROM THE ELECTRICITY SUPPLY.

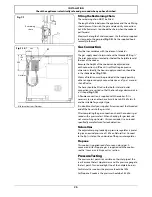

Remove the pan supports and burner heads. Remove

the screws holding the hotplate burners to the hotplate.

Remove the 6 screws holding the hotplate tray to the

cooker (Fig.9-2).

Taking care not to damage the burner electrodes,

carefully lift the hotplate. From underneath, disconnect

the earth lead at the right-hand rear from the rear cross

member and withdraw the hotplate.

Reassemble in reverse order, making sure that you

reconnect the leads. Take care not to damage the

burner ignition electrodes.

IMPORTANT:

Make sure you replace the rear earthing

leads when refitting the fixing screws as they form

part of the cooker earthing.

Check for correct burner operation.

2.2 To Replace the Hotplate Control Taps

DISCONNECT FROM THE ELECTRICITY SUPPLY.

n

n

BEFORE SERVICING ANY GAS CARRYING

COMPONENTS, TURN OFF THE GAS SUPPLY.

Remove the control panel and hotplate (see 1.1 & 2.1).

Unplug the FSD lead from the rear of the tap. Undo the

compression fitting at the rear of the tap and remove

the fixings that secure the tap to the gas rail. Disconnect

the ignition switch wiring.

Remove the tap. Remove and discard the gasket seal. Fit

the new gasket seal to the replacement tap. Reassemble

in reverse order. Check that the appliance is gas sound.

Verify the hotplate ignition.

2.3 To Change a Hotplate Burner Injector

Remove the burner cap and head. Remove the old jet.

Fit the new injector. Reassemble in reverse order. Check

the appliance is gas sound.

2.4 To Replace a Hotplate Burner Electrode

Lift off pan supports and remove the burner cap.

Remove the screw holding the electrode. Pull the

electrode vertically up sufficiently to grip the lead

between thumb and forefinger.

Pull off the electrode, but keep hold of the lead. Fit

the new electrode to the lead. Fix the electrode in the

burner with screw. Replace the burner cap.

Check the burner ignition. Replace the pan supports.

2.5 To Replace a Hotplate Burner

Remove the hotplate tray (see 2.1). The burners (except

the right-hand wok burner) are mounted on support

struts. For these burners, disconnect the burner feed

pipes at the burner. Remove the screws at the front

and rear holding the support struts. Lift the strut and

burners clear.

The burners are fixed to the support struts with 2

screws. Remove the appropriate burner and fit the new

one.

Reassemble in reverse order. Check that the burner

operation is satisfactory.

Right-hand Wok Burner

Disconnect the burner feed pipes at the burner. Fit the

new one and reassemble in reverse order. Check the

burner operation.

3 Control Panel

3.1 To Replace the Ignition or light Switch

DISCONNECT FROM THE ELECTRICITY SUPPLY.

Remove the control panel (see 1.1).

Note: The old switch may be destroyed during removal.

Remove the old switch from its bezel by gripping the

switch body behind the control panel and twisting

sharply. Remove the switch bezel by folding back the

locking wings and pushing forward.

To fit the new bezel to the control panel, first line up the

raised key on its body with the cut-out in the control

panel and push it in from the front.

Assemble the new switch to the bezel by lining up the

key sections and pushing home. Fit the new button by

pushing in from the front.

Replace the control panel in reverse order and test for

correct operation.

3.2 To Replace the Clock

DISCONNECT FROM THE ELECTRICITY SUPPLY.

Remove the control panel (see 1.1). Pull off the timer

control buttons.

Undo the timer fixing screws and remove the timer

mounting bracket assembly from the control panel.

Remove the timer from its mounting bracket by

depressing the plastic lugs on the timer case, and at the

same time pulling the unit forward.

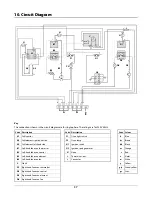

Reassemble in reverse order. When replacing the leads,

refer to the wiring diagram. Check the operation of the

timer.

3.3 To Change the Ignition Generator

DISCONNECT FROM THE ELECTRICITY SUPPLY.

Pull the cooker forwards to gain access to the cover box

at the rear of the cooker. Remove the screws securing

the cover and lift clear. Pull off all the leads to the

generator noting their positions. Slacken the 2 screws

holding generator to cooker and remove the generator.

Fit the new generator to the cooker and replace the

leads. Refer to the wiring diagram and reassemble in

reverse order. Check ignition performance.