34

WARNING - SERVICING TO BE CARRIED OUT ONLY BY AN AUTHORISED PERSON

Disconnect from electricity and gas before servicing. Check appliance is safe when you have finished.

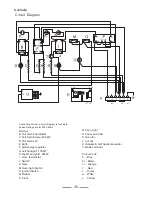

19. To Change Ignition Generator

Disconnect from electricity supply.

Pull cooker forward to gain access to the cover box at

the rear of the cooker. Remove the screws securing the

cover and lift clear. Pull off all the leads to the

generator noting their positions. Slacken the two

screws holding generator to cooker and remove

generator.

Fit new generator to cooker and replace leads.

Reassemble in reverse order. Refer to wiring diagram.

Check ignition performance.

20. To Remove an Oven Inner Back.

Left hand oven

Open LH oven door and remove 4 screws and washers

securing the inner back to the back of the oven.

Carefully lift away the inner back. Reassemble in

reverse order making sure that the 4 screws and

washers are fully tightened.

Right hand Tall oven

Open RH oven door and remove 2 screws and washers

securing the inner back to the back of the oven.

Carefully lift away the inner back. Reassemble in

reverse order making sure that the screws and

washers are fully tightened.

21. To Change an Oven Fan

Disconnect from electricity supply.

Pull cooker forward to gain access to the rear. Remove

screws securing the electric cover to the back sheet

and remove cover. Disconnect the 3 terminals

connected to the fan noting their position. Remove

oven inner back (see 20). Hold the fan blade and

remove the centre nut (left hand thread) 2 brass

washers, fan blade and circlip. Unscrew fan retaining

nuts and washers (3 off each) and lift the fan away

from the rear of the cooker. Fit new fan and

reassemble in reverse order. Check operation of oven.

22. To Remove an Oven Element.

Disconnect from electricity supply.

Pull cooker forward to gain access to the rear. Remove

screws securing the electric cover to the back sheet

and remove cover. Disconnect the 3 terminals

connected to the element noting their position. Remove

oven inner back (see 1). Remove 2 screws from the top

of the element and 1 from the bottom of the element in

side the oven. Lift out carefully, refit new element,

reassemble in reverse order. Check operation of oven.

23. To Remove Grill Element.

Disconnect from electricity supply.

Pull cooker forward to gain access to the rear. Remove

screws securing the electric cover to the back sheet

and remove cover. Remove the 4 terminals connected

to the elements noting their position. Remove grill pan

from grill chamber. From inside grill compartment

remove enamelled front shield from grill roof, 2 screws

and washers. Remove 2 screws and washers securing

the grill element front support. Remove 1 screw from

each of the grill elements and withdraw grill elements

from grill chamber. Fit new elements, reassemble in

reverse order. Check operation of grill.

24. To change oven light bulb.

Remove the oven furniture. Unscrew the bulb cover by

turning anticlockwise. Unscrew the bulb. Fit an Edison

screw fitting 15w 240v lamp, FOR OVENS. It must be a

special bulb, heat resistant to 300°C.

Screw in the new bulb, screw back the bulb cover. Turn

on the electricity supply and check that the bulb now

lights.