INSTALLATION

Check the appliance is electrically safe and gas sound when you have finished.

26

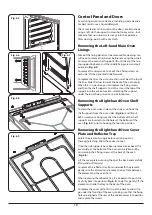

Stability chain

ArtNo.010-0004 Moving the cooker

Lowering the Two Rear Rollers

To adjust the height of the rear of the cooker, first fit a 13 mm

spanner or socket wrench onto the hexagonal adjusting

). Rotate the nut – clockwise to raise – counter-

clockwise to lower.

Make 10 complete (360°) turns clockwise.

Make sure you lower BOTH REAR ROLLERS.

Completing the Move

Unfold the rear edge of the pack base tray. We recommend

that you remove the oven doors to move the cooker. Open

the oven door fully and place the supplied holding pins in the

drop down hinges (

Carefully lift the door panel up and out, place safely to one

side. You can now get a good grip from inside of the oven

(not the fascia panel) as you move the oven (

).

Carefully push the cooker backwards off the cardboard base.

Remove the pack base tray.

Position the cooker close to its final position, leaving just

enough space to get behind it.

After moving, carefully refit the door panel and push down

gently to release the holding pins.

n

Do not use the door handles or control knobs to

manoeuvre the cooker.

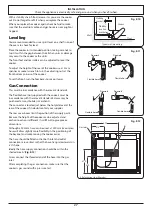

Fitting the Stability Bracket or

Chain

Unless otherwise stated, a cooker using a flexible gas

connector must be secured with a suitable stability device.

Suitable stability devices are shown in

,

.

If you are using a stability chain (

should be kept as short as is practicable and fixed firmly to

the rear of the cooker.

If you are using a stability bracket; first attach the bracket

location device to the rear of the cooker (

). Then

adjust the bracket to engage through the slot of the device

).

Repositioning the Cooker

Following Connection

If you need to move the cooker once it has been connected

then you need to unplug it and, having gripped under the

fascia panel and lifted the front of the cooker slightly

), you need to check behind the cooker to make sure

that the gas hose is not caught.

As you progress, make sure that both the electricity cable and

gas hose always have sufficient slack to allow the cooker to

move.

Fig. 8.4

Fig. 8.5

Fig. 8.6

Fig. 8.7

Alternative positions

for stability location

bracket

ArtNo.070-0014 - Stability bracket - Wall fitting

Cooker

Stability bracket

Floor

Stability

location

bracket

Typical floor mounting

Fig. 8.8

Fig. 8.9