PARTS IDENTIFICATION

All coupling parts have identifying part numbers as shown

below. Parts 3 and 4 (Hubs and Grids), are the same for both

Type T10 and T20 couplings. All other coupling parts are

unique to Type T10. When ordering parts, always SPECIFY SIZE

and TYPE shown on the COVER.

PARTS INTERCHANGEABILITY

Parts are interchangeable between Sizes 20T and 1020T, 30T

and 1030T, etc. except as noted.

GRIDS — Size 1150T thru 1260T Steelflex couplings use blue

grids. Older models, 150T thru 260T, use orange grids.

CAUTION:

Blue grids may be used in all applications, but DO

NOT substitute orange grids for blue.

CAUTION:

DO NOT mix cover halves of different designs.

WARNING:

Mixing grid coupling components from different

manufacturers may cause premature failure and personal or

property damage from flying debris.

®

The Falk Corporation, P.O. Box 492, Zip 53201-0492

428-112

3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone: 414-342-3131

May 2000

Fax: 414-937-4359 e-mail: falkinfo@falkcorp.com web: www.falkcorp.com

Supersedes 12-98

Installation and Maintenance

•

Steelflex

®

Couplings

(Page 6 of 6)

Sizes 1150–1260 & 150–260

•

Types T10

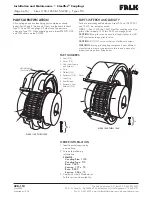

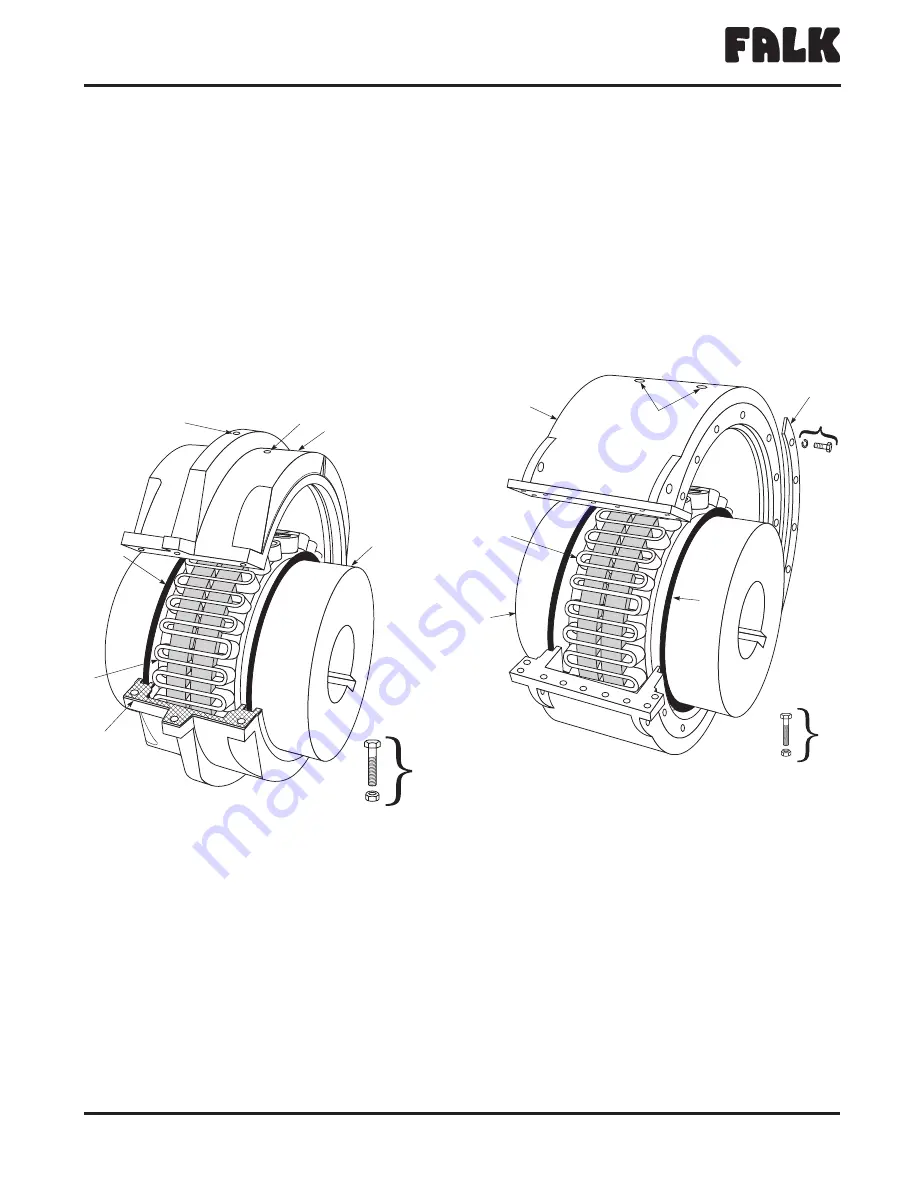

PART NUMBERS

1. Seal (T10)

2. Cover (T10)

3. Hub (Specify bore

and keyway)

4. Grid

5. Gasket (T10)

6. Fasteners (T10) — Cover

7. Lube Plug

8. Seal Retainer

9. Fasteners, Seal

Retainer (T10)

ORDER INFORMATION

1. Identify part(s) required by

name above.

2. Furnish the following

information.

EXAMPLE:

Coupling Size: 1150

Coupling Type: T10

Bore: 7.500

Keyway: 1.75 x .75

Bore: 8.000

Keyway: 2.00 x .75

3. Contact your Falk Distributor or

Falk for price and availability.

LIFTING HOLE

(Cover Only)

7

2

3

1

4

5

SIZES 1150 THRU 1230

6

2

7

8

9

6

1

3

4

SIZES 1240 THRU 1260